38

RECOMMENDED LUBRICANT

The Model 2100 requires periodic lubri-

cation of the motors and speed reduction

units. Speed reduction units, which drive

the feed screw and agitator, are mounted

on the end of the feed hopper (Figure 23).

The units are filled with oil at the time of

shipment and should be checked for

correct level before starting the machine.

Correct oil level must be maintained for

adequate lubrication of gears and bear-

ings, and to insure maximum life of the

speed reduction units.

Oil level is checked by removing the oil

level pipe plugs located at the horizontal

center line of each housing (Figure 24).

The vented filler plug is located in the

uppermost position in the housing. The

arrow on the plug should point up. The

drain plug is located in the lowest position

in the housing.

Oil capacity is 1-1/2 U.S. quarts (1.4

liters) for the agitator speed reduction unit

and 3 quarts (2.8 liters) for the feed screw

speed reduction unit. Use a lubricant such

as Mobil DTE No. 26 Hydraulic Oil or

equivalent. See reduction unit manufac-

turer’s instructions for additional specifica-

tions.

After an initial run of approximately 250

hours, the housings should be drained,

preferably while warm. Refill to the proper

level with fresh oil. Under normal condi-

tions oil should be replaced at regular

intervals of 2500 hours of operation or six

months, whichever occurs first.

NOTE:

Oil should be changed more

frequently if the unit is operated in chemi-

cal fumes, extremely moist, dusty or high

ambient temperature conditions.

Temperature of the reduction units may

reach 160°F (71°C) when new or under

extremely warm ambient conditions. This

temperature will not affect operation of the

units. Do not allow the units to operate

over 225°F (107°C). Check for overload or

high ambient temperature. For additional

information, consult reduction unit manu-

facturer’s instructions supplied with the

machine.

MAINTENANCE

Lubrication

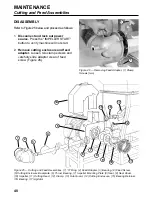

Figure 23 — Belt Guard Cover removed showing

speed reduction units. (1) Speed Reduction Units

Figure 24 — Speed Reduction Unit (feed screw).

(1) Vented Filler Plug, (2) Oil Level Pipe Plug,

(3) Drain Plug

2

1

3

1

Содержание COMITROL 2100

Страница 2: ......

Страница 28: ...Addendum A 26 This page intentionally left blank...

Страница 84: ...6 This page intentionally left blank...

Страница 94: ...16 This page intentionally left blank...

Страница 95: ...17 GENERAL INFORMATION...

Страница 101: ...23 INSTALLATION...

Страница 104: ...26 This page intentionally left blank...

Страница 110: ...32 This page intentionally left blank...

Страница 131: ...53 PARTS...

Страница 132: ...54 This page intentionally left blank...

Страница 134: ...56 PARTS Tools See the Addendum for updated information...

Страница 138: ...60 PARTS Agitator Feed Screw See the Addendum for updated information...

Страница 140: ...62 PARTS Cutting Assembly 8 3 4 5 2 5 1 6 7 9 12 11 10 14 16 26 25 24 23 22 21 17 18 19 20 13 15...

Страница 146: ...PARTS Motor and Drive Parts 68 See the Addendum for updated information...

Страница 148: ...PARTS Electrical Assembly NEMA 70 See the Addendum for updated information...

Страница 150: ...PARTS Electrical Assembly NEMA 72 59 58 57 17 16 15 1 14 See the Addendum for updated information...

Страница 152: ...PARTS Electrical Assembly CE compliant 74 See the Addendum for updated information...

Страница 156: ...78 PARTS Electrical Assembly Switches See the Addendum for updated information...

Страница 165: ......