Start-up and Shut-dow n

CVHH-SVX001A-EN

81

Control Panel Devices and Unit-

M ounted Devices

Unit Control Panel

Safety and operating controls are housed in the unit

control panel, the starter panel, and the purge control

panel. The control panel operator interface and m ain

processor is called Tracer AdaptiView and is located on an

adjustable arm connected to the base of the control panel.

For m ore inform ation about operating Tracer AdaptiView,

refer to Tracer AdaptiView ™ Display for Water-Cooled

CenTraVac™ Chillers Operations Guide (CTV-SVU01D-EN,

or the m ost recent version).

The control panel houses several other controls m odules

called panel m ounted LLID (Low Level Intelligent Device),

pow er supply, term inal block, fuse, circuit breakers, and

transform er. The IPC (Interprocessor com m unication) bus

allow s the com m unications betw een LLIDs and the m ain

processor. Unit m ounted devices are called fram e

m ounted LLIDs and can be tem perature sensors or

pressure transducers. These and other functional sw itches

provide analog and binary inputs to the control system .

User-Defined Language Support

Tracer AdaptiView is capable of displaying English text or

any of tw enty-four other languages. Sw itching languages

is sim ply accom plished from a language settings m enu.

Unit Start-up and Shut-dow n

Procedures

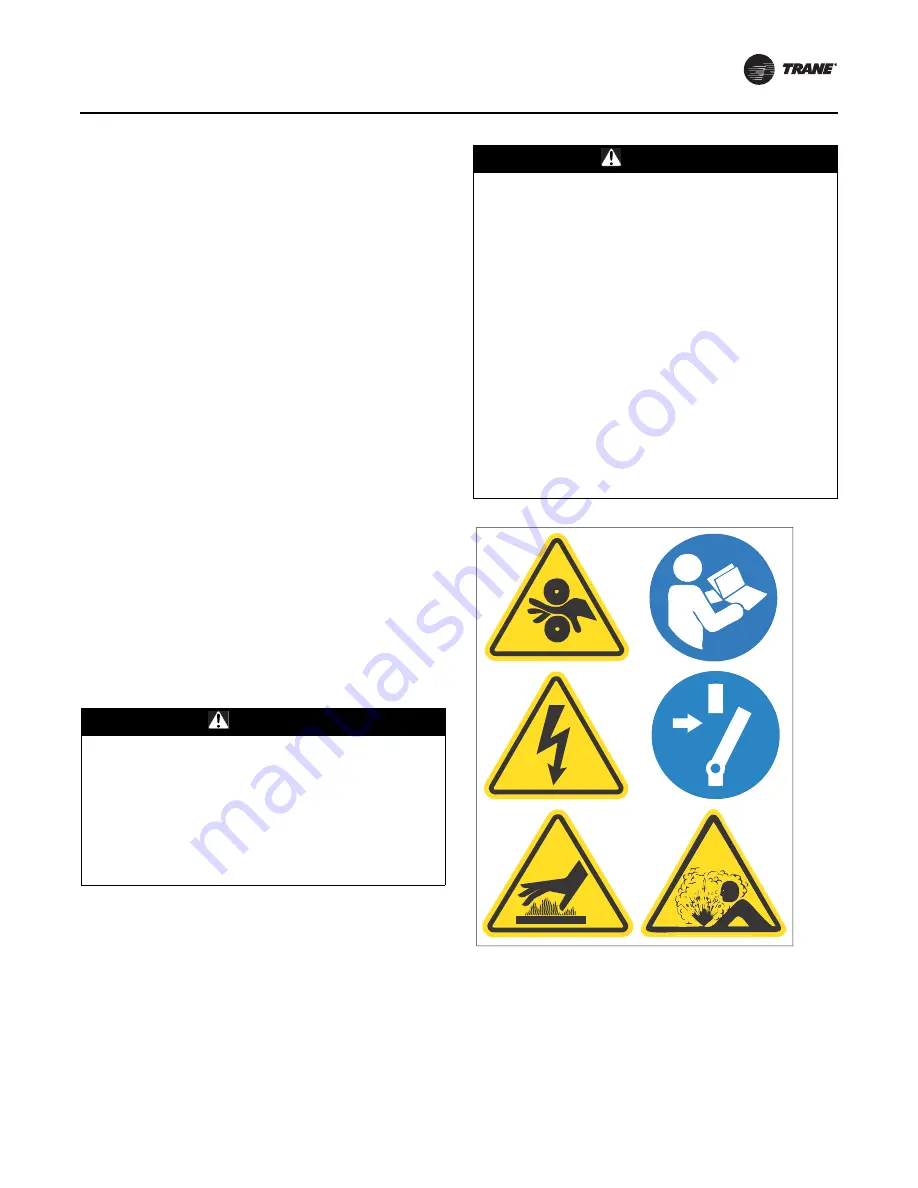

N ot e: Graphic labels (show n above) are used for CE

application only.

Im port ant :

•

Before servicing, disconnect all pow er sources and

allow at least 30 m inutes for capacitors to discharge.

•

All electrical enclosures—unit or rem ote—are IP2X.

WARNING

Live Electrical Components!

Failure to follow all electrical safety precautions w hen

exposed to live electrical components could result in

death or serious injury. During installation, testing,

servicing and troubleshooting of this product, it may be

necessary to work w ith live electrical components.

Have a qualified licensed electrician or other individual

w ho has been properly trained in handling live

electrical components perform these tasks.

WARNING

Toxic Hazards!

Do not allow the chiller to increase above 54.4°C (130°F)

in temperature w hile unit is off. Failure to prevent high

chiller temperature w ill cause the inside pressure to

rise:

•

Do not run evaporator water pump longer than

30 minutes after the chiller is shut dow n.

•

Ensure that the evaporator is isolated from the hot

w ater loop before changeover to heating mode.

The rupture disk is designed to relieve and discharge

the refrigerant from the unit if the pressure in the

evaporator exceeds 344.7 kPag (50 psig). A significant

release of refrigerant into a confined space due to a

rupture disk failure could displace available oxygen to

breathe and cause possible asphyxiation. Should a

rupture disk fail, evacuate the area immediately and

contact the appropriate rescue or response authority.

Failure to follow instructions could result in death or

serious injury.

X39003892001A

Содержание CVHH

Страница 110: ......