MAINTENANCE MANUAL

176

STE 85357

In principle, grease should be applied to the ball screw spline unit every three months.

Be sure to apply grease whenever there is a shortage of grease.

At daily inspection also, make sure that the ball screw spline unit is filled with a

sufficient volume of grease.

Check the condition of anticorrosive in daily inspection. If anticorrosive is dried up,

apply it.

Table 4.7 Recommended anticorrosive (THL800, THL900, THL1000)

Recommended anticorrosive

Maker

KLUBER A20

NOK

WD-40

ST TRADING

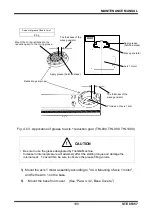

Fig. 4.41 Applying anticorrosive and grease to ball screw spline unit

(THL800, THL900, THL1000)

1)

Remove the arm 2 cover (see “Para. 4.3.1, Arm 2 Cover.”)

2)

Connect the controller power supply plug and turn off the servo system.

3)

Move the arm to a position where Axis 3 can be moved over the full stroke by

hand.

4)

Push down the ball screw spline shaft to the lower limit while pressing the axis 3

brake release switch.

Apply a rust

inhibitor to the

end face as

well.

Apply grease to the

thread groove,

spline groove and

outer peripheral

portion uniformly.

Apply anticorrosive onto a

waste cloth, and wipe the

top and side surfaces of

the ball screw nut with it.

Upside (without arm 2 cover)

Apply anticorrosive onto a waste

cloth, and wipe the bottom and side

surfaces of the spline nut with it.

Downside