MAINTENANCE MANUAL

109

STE 85357

Note that if the ball screw nut is pulled out of the shaft, the ball falls off from the

ball screw nut and, consequently, the ball screw spline unit can no longer be

used.

5)

Disconnect the axis 3 timing belt.

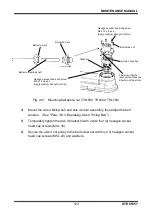

Fig. 3.29 Replacing axis 3 timing belt (THL500, THL600, THL700)

6)

Mount the new timing belt. Insert the ball screw spline shaft into the ball spline

nut, and mount the stoppers. (For the insertion of the ball screw spline shaft,

see “Para. 3.6.5, Mounting Ball Screw Spline Unit.”)

7)

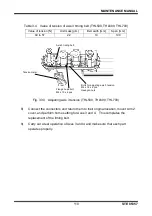

Hang the timing belt to the axis 3 motor assembly which was previously

removed in 3), and temporarily secure it to Arm 2 with four (4) flange head bolts

(M4 x 10, application of Loctite not necessary). Move the ball screw spline unit

up and down to make it fit in. Apply tension using two (2) axis 3 tension

adjustment bolts (M4 x 16, application of Loctite not necessary).

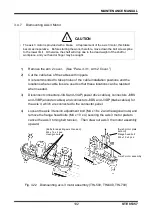

While pulling the axis 3 motor plate with the axis 3 tension adjustment bolts,

measure the tension with a tension meter. Tighten the flange head bolt at the

location where the tension reaches a value slightly smaller than 49 N (because

the tension gets larger by retightening of the flange head bolt). Adjust so that

the tensile value becomes between 49 and 57 N when the flange head bolt is

retightened. Then, secure with the hex nut.

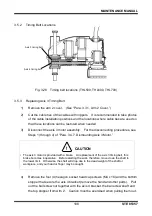

The values to be used for the tension meter are as shown in the table below.

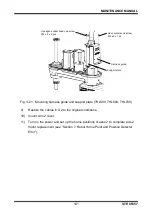

Ball screw spline shaft

Hexagon socket head cap screws

M4 x 16 x 4 pcs.

Axis 4 bracket

Stopper

Stopper

Ball screw nut

Axis 3 timing belt