MAINTENANCE MANUAL

100

STE 85357

5)

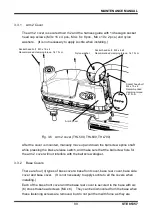

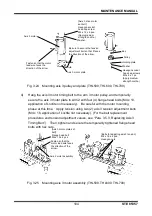

Secure the axis 2 motor with four (4) hexagon socket head cap screws (M4 x

16) and washers.

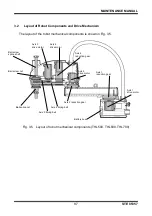

Fig. 3.20 Mounting axis 2 motor assembly (THL500, THL600, THL700)

!

CAUTION

• Do not forget to mount the O-ring.

If the O-ring is not mounted, grease will leak from the motor mounted surface.

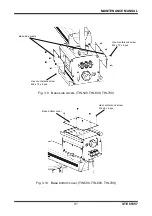

6)

Secure the harness guide and the support plate with one (1) hex countersunk

screw (M4 x 8, application of Loctite not necessary) and two (2) hexagon socket

head cap screws (4 x 8).

7)

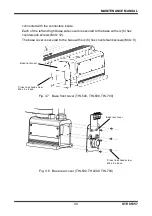

Move Arm 2 by hand and check that there is no abnormal sound before turning

on the power.

8)

Connect J2AS and J2AP (axis 2 power drive cables), J2BS and J2BP (axis 2

encoder cables).

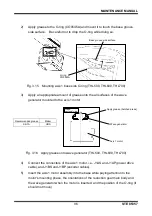

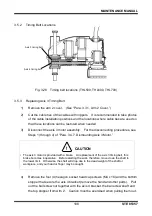

Axis 2 Motor Cross Section Diagram

Install the O-ring as shown in

the figure.

[Axis 2 drive motor

set bolt]

Hexagon socket

head cap screw

M4 x 14 x 4 pcs.

(Apply medium

strength Loctite.)

Washer

O-ring

CO0538A

Inlaid part

Axis 2 motor

Fasten so that the motor lead wire

faces the direction of the arrow.

Axis 2 motor

assembly