MAINTENANCE MANUAL

135

STE 85357

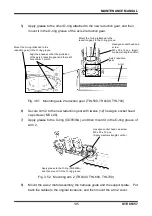

5)

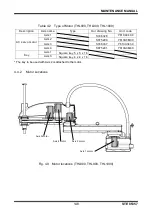

Apply grease to the other O-ring attached to the new reduction gear, and then

mount it in the O-ring groove of the axis 2 reduction gear.

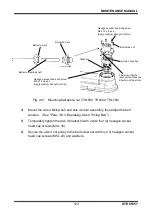

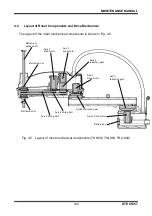

Fig. 3.51 Mounting axis 2 reduction gear (THL500, THL600, THL700)

6)

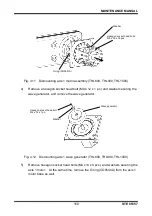

Secure Arm 2 to the new reduction gear with twelve (12) hexagon socket head

cap screws (M3 x 20).

7)

Apply grease to the O-ring (CO0538A), and then mount it in the O-ring groove of

Arm 2.

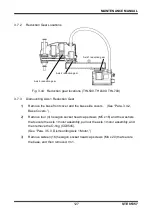

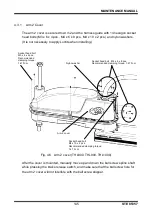

Fig. 3.52 Mounting arm 2 (THL500, THL600, THL700)

8)

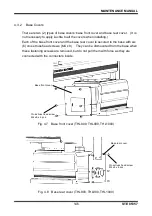

Mount the axis 2 motor assembly, the harness guide and the support plate. Put

back the cables to the original locations, and then mount the arm 2 cover.

Axis 2 reduction

gear

Arm 1

Mount the O-ring (attached to the

reduction gear) in the O-ring groove.

Hexagon socket head cap

screw

M3 x 30 x 12 pcs.

(Apply

medium strength Loctite.)

Align the phases so that the protrusion

of the axis 2 reduction gear and the relief

hole of Arm 1 match.

Mount the O-ring (attached to the

reduction gear) in the O-ring groove.

Hexagon socket head cap screw

M3 x 20 x 12 pcs.

(Apply medium strength Loctite.)

Apply grease to the O-ring (CO0538A),

and then mount it in the O-ring groove.