24

7.16 De-Air sequence.

The De-Air sequence it is a safety function starting at every power ON and is used to remove the air from the heat-

exchanger. The De-Air sequence also starts after a general reset (such as the locking error reset or 24 hours reset)

The display will show ‘dAir’ indicating that the controller is performing the De-Air sequence to purge the heat

exchanger of air, by sequencing the pump OFF and ON. The user can cancel the De-Air sequence by pressing a

specific key-button combination from the display. By default “De-Air” sequence takes around 14 minutes.

• 1st cycle: The 3 ways valve moves to CH position and the general pump is activated for 10 seconds, deactivated

for 10 seconds, activated again for 10 seconds and then deactivated again for 10 seconds (DAir_Repeation_OnOff,

which means ON/OFF/ON/OFF each time for 10 seconds = 40 seconds in total).

• 2nd cycle: it starts when 1st cycle is ended. The 3 ways valve is moved to DHW position and repeats the same

cycling of the pump (DAir_Repeation_OnOff, which means ON/OFF/ON/OFF each time for 10 seconds = 40 second

in total).

This sequence (1st 2nd cycles) is performed DAir_Number_Cycles times (if DAir_Number_Cycles is 3 ‘De-

air’ sequence lasts (3 x 40) x 2 = 240 seconds).

During De-Air sequence no demand will be served. When the water pressure is too low or pressure sensor is in

error, the De-Air sequence will be suspended until water pressure / sensor pressure is stable again. In that case

the De-Air sequence will last longer than the estimated minutes.

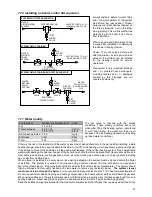

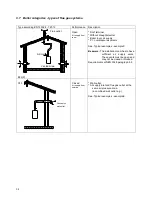

The following scheme below shows the behaviour of the 3-way valve and general pump during one whole cycle of

De-Air sequence with a DAir_Repeation_OnOff set to 2.

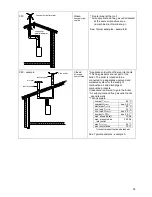

Relevant variables:

Specific Parameters

Level

(Default) Value

Range

De-Air Config

Configuration for the De-Air function

2:

Installer

1

0: 24 hr pump

1: De-Air

2: Disabled

De-Air State

1: User

-

-

Current state of the De-Air function.

De-Air Repeation Cnt

On/Off repeation count for a De-Air cycle.

2:

Installer

2

0…255

De-Air Cycles

Number of De-Air cycles.

2:

Installer

3

0…255

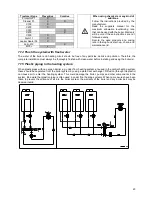

7.17 Automatic Feed Valve systems

If an automatic feed valve is installed in the system, it should not be left open indefinitely. A continuous feed of

fresh water could damage the system (fresh water is bringing fresh oxygen into the system). It is recommended

that after a short period of time following the installation of the boiler into a heating system that the automatic feed

valve be closed

When using an automatic water refill system some precautions should be taken (fresh water is bringing fresh oxygen

into the system), like installing a water meter to measure and evaluate the total water volume that is added to the

system. This to detect and eliminate any water leakage as soon as possible.

When an automatic water refill system is used, some form of logging should take place to prevent continuously

filling of the system with large amounts of oxygenated fresh water. This can happen when a leak in the system is

not detected and the total added water amount is not being logged.

Содержание S-CBX 105

Страница 2: ......

Страница 40: ...40 9 10 Flue Terminal Positioning ...

Страница 42: ...42 9 11 1 FIGURE 12 LINE G ...

Страница 55: ...55 11 5 Ladder Logic Diagram ...

Страница 56: ...56 11 6 Electrical schematics ...

Страница 57: ...57 ...

Страница 137: ......