32

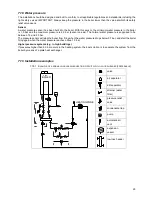

9.4 Air supply

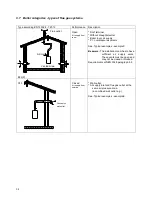

When an air supply duct is connected from the outside of the building to the boiler, the boiler will operate as a room-

independent boiler (closed boiler).

The air supply duct can be made of PVC, PP or Stainless steel

9.4.1 C

OMBUSTION AIR QUALITY

Combustion air must be free of contaminants. For example: chlorine, ammonia and/or alkali agents, dust, sand and

pollen. Remind that installing a boiler near a swimming pool, a washing machine, laundry or chemical plants does

expose combustion air to these contaminants.

9.4.2 A

IR SUPPLY THROUGH HUMID AREAS

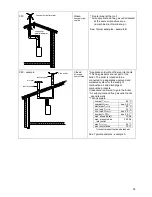

When the supply duct will be placed in a boiler room with moist air (for example: greenhouses), a double walled

supply duct or an insulated duct must be used to prevent the possible condensation at the outside of the duct. It is

not possible to insulate the internal air pipes of the boiler and therefore condensation at the internal air canals must

be prevented.

When roof mounted, the air supply duct needs to be protected against rain, so no water will be entering the boiler.

9.4.3 A

IR INLET PIPE MATERIALS

The air inlet pipe(s) must be sealed. Choose acceptable combustion air inlet pipe materials from the following list:

- PVC or PP

- Flexible propylene air intake

- Galvanized steel vent pipe with joints and seams sealed as specified in this section.

9.5 Room air

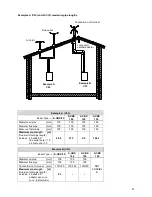

Commercial applications utilizing the boiler may be installed with a single pipe carrying the flue products to the

outside while using combustion air from the equipment room. In order to use the room air venting option, the

following conditions and considerations must be followed.

• The equipment room MUST be provided with properly sized openings to assure adequate combustion air.

• There will be a noticeable increase in the noise level during normal operation from the inlet air opening.

• Vent system and terminations must comply with the standard venting instructions set forth in this manual.

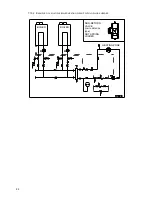

9.5.1 A

IR CONTAMINATION

Pool and laundry products and common household and hobby products often contain fluorine or chlorine

compounds. When these chemicals pass through the boiler, they can form strong acids. The acid can eat through

the boiler wall, causing serious damage and presenting a possible threat of flue gas spillage or boiler water leakage

into the building.

Please read the information given in the list below, with contaminants and areas likely to contain them. If

contaminating chemicals will be present near the location of the boiler combustion air inlet, have your installer pipe

the boiler combustion air and vent to another location, per this manual.

The boiler should never be located in a laundry room or pool facility, for example, these areas

will always contain hazardous contaminants.

To prevent the potential of severe personal injury or death, check for areas and products

listed in the list below, with contaminants before installing the boiler or air inlet piping.

If contaminants are found, you MUST: - remove contaminants permanently.

or - relocate air inlet and vent terminations to other areas.

WARNING

Содержание S-CBX 105

Страница 2: ......

Страница 40: ...40 9 10 Flue Terminal Positioning ...

Страница 42: ...42 9 11 1 FIGURE 12 LINE G ...

Страница 55: ...55 11 5 Ladder Logic Diagram ...

Страница 56: ...56 11 6 Electrical schematics ...

Страница 57: ...57 ...

Страница 137: ......