Setting up the machine

2.10 Handwheel assignment

Milling

Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

111

2.10

Handwheel assignment

You can traverse the axes in the machine coordinate system (Machine) or in the workpiece

coordinate system (Work) via the handwheel.

Software option

You require the "Extended operator functions" option for the handwheel

offset (only for 828D).

All axes are provided in the following order for handwheel assignment:

●

Geometry axes

When traversing, the geometry axes taken into account the actual machine status (e.g.

rotations, transformations). All channel machine axes, which are currently assigned to the

geometry axis, are in this case simultaneously traversed.

●

Channel machine axes

Channel machine axes are assigned to the particular channel. They can only be

individually traversed, i.e. the actual machine state has no influence.

The also applies to channel machine axes, that are declared as geometry axes.

Machine manufacturer

Please refer to the machine manufacturer's specifications.

Procedure

1.

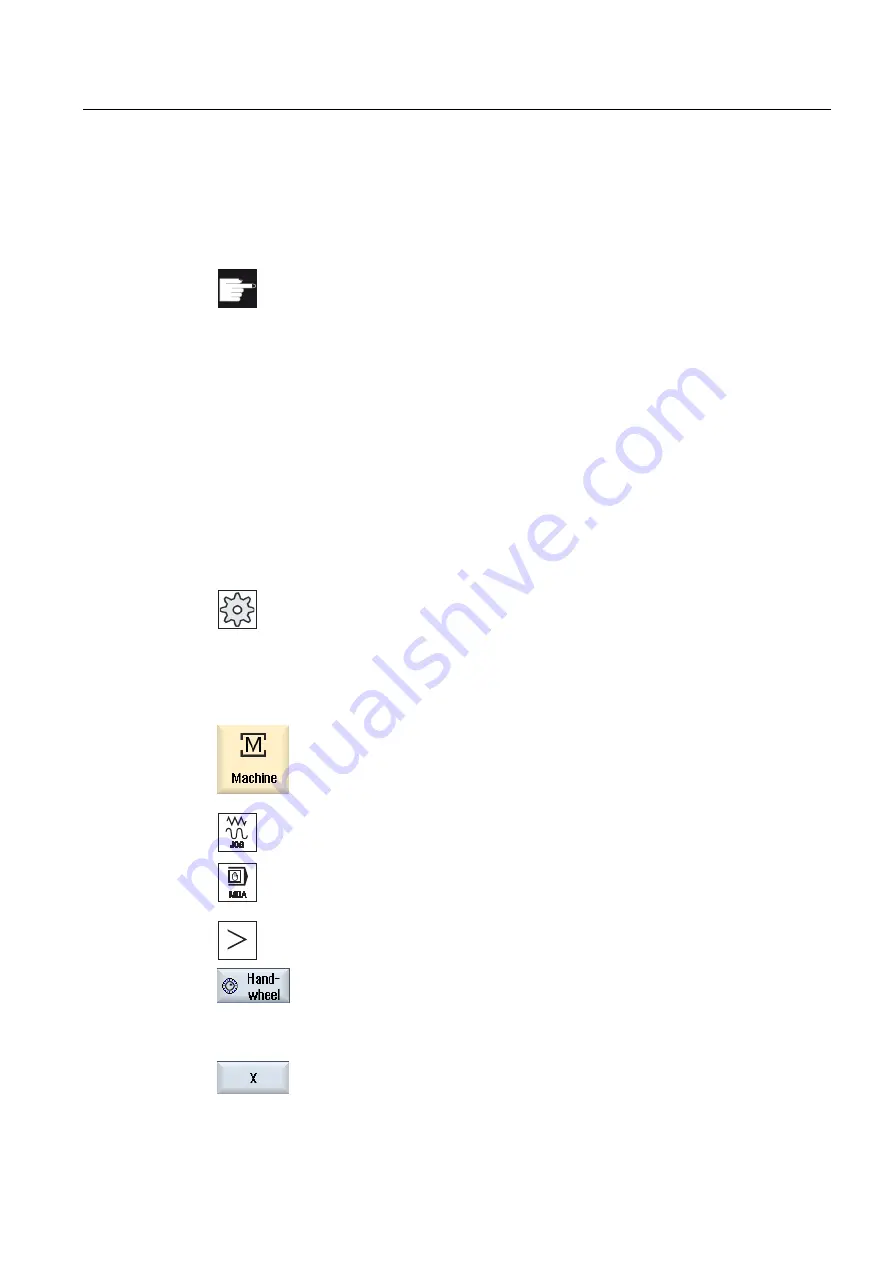

Select the "Machine" operating area.

Press the <JOG>, <AUTO> or <MDA> key.

2.

Press the menu forward key and the "Handwheel" softkey.

The "Handwheel" window appears.

A field for axis assignment will be offered for every connected

handwheel.

3.

Position the cursor in the field next to the handwheel with which you

wish to assign the axis (e.g. No. 1).

4.

Press the corresponding softkey to select the desired axis (e.g. "X").

Содержание SINUMERIK 840D

Страница 6: ...Preface Milling 6 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 50: ...Introduction 1 4 User interface Milling 50 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 134: ...Execution in manual mode 3 7 Default settings for manual mode Milling 134 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 172: ...Machining the workpiece 4 13 Setting for automatic mode Milling 172 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 194: ...Simulating machining 5 9 Displaying simulation alarms Milling 194 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 207: ...Creating G code program 6 8 Selection of the cycles via softkey Milling Operating Manual 03 2010 6FC5398 7CP20 1BA0 207 ...

Страница 208: ...Creating G code program 6 8 Selection of the cycles via softkey Milling 208 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 209: ...Creating G code program 6 8 Selection of the cycles via softkey Milling Operating Manual 03 2010 6FC5398 7CP20 1BA0 209 ...

Страница 216: ...Creating G code program 6 10 Measuring cycle support Milling 216 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 264: ...Creating a ShopMill program 7 17 Example standard machining Milling 264 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 440: ...Multi channel view 9 3 Setting the multi channel view Milling 440 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 460: ...Teaching in a program 11 7 Deleting a block Milling 460 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 600: ...Appendix A 2 Overview Milling 600 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 610: ...Index Milling 610 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...