Setting up the machine

2.7 Work offsets

Milling

102

Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

Procedure

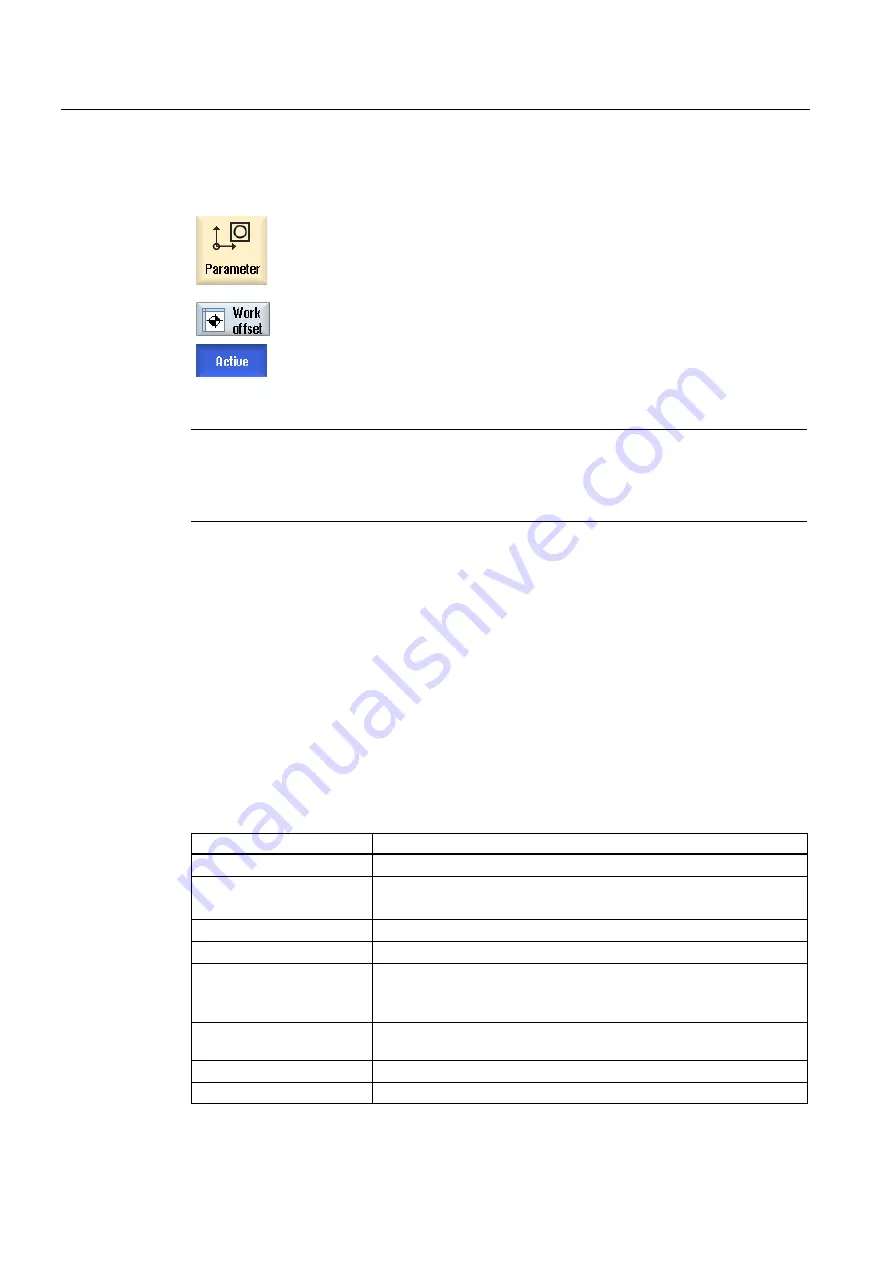

1.

Select the "Parameter" operating area.

2.

Press the "Work offset" softkey.

The "Work Offset - Active" window is opened.

Note

Further details on work offsets

If you would like to see further details about the specified offsets or if you would like to

change values for the rotation, scaling or mirroring, press the "Details" softkey.

2.7.2

Displaying the work offset "overview"

The active offsets or system offsets are displayed for all set-up axes in the "Work Offset -

Overview" window.

In addition to the offset (course and fine), the rotation, scaling and mirroring defined using

this are also displayed.

This window is generally used only for monitoring.

Display of active work offsets

Work offsets

DRF

Displays the handwheel axis offset.

Basic reference

Displays the additional work offsets programmed with $P_SETFRAME.

Access to the system offsets is protected via a keyswitch.

External WO frame

Displays the additional work offsets programmed with $P_EXTFRAME.

Total base WO

Displays all effective basis offsets.

G500

Displays the work offsets activated with G54 - G599.

Under certain circumstances, you can change the data using "Set

WO", i.e. you can correct a zero point that has been set.

Tool reference

Displays the additional work offsets programmed with

$P_TOOLFRAME.

Workpiece reference

Displays the additional work offsets programmed with $P_WPFRAME.

Programmed WO

Displays the additional work offsets programmed with $P_PFRAME.

Содержание SINUMERIK 840D

Страница 6: ...Preface Milling 6 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 50: ...Introduction 1 4 User interface Milling 50 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 134: ...Execution in manual mode 3 7 Default settings for manual mode Milling 134 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 172: ...Machining the workpiece 4 13 Setting for automatic mode Milling 172 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 194: ...Simulating machining 5 9 Displaying simulation alarms Milling 194 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 207: ...Creating G code program 6 8 Selection of the cycles via softkey Milling Operating Manual 03 2010 6FC5398 7CP20 1BA0 207 ...

Страница 208: ...Creating G code program 6 8 Selection of the cycles via softkey Milling 208 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 209: ...Creating G code program 6 8 Selection of the cycles via softkey Milling Operating Manual 03 2010 6FC5398 7CP20 1BA0 209 ...

Страница 216: ...Creating G code program 6 10 Measuring cycle support Milling 216 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 264: ...Creating a ShopMill program 7 17 Example standard machining Milling 264 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 440: ...Multi channel view 9 3 Setting the multi channel view Milling 440 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 460: ...Teaching in a program 11 7 Deleting a block Milling 460 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 600: ...Appendix A 2 Overview Milling 600 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...

Страница 610: ...Index Milling 610 Operating Manual 03 2010 6FC5398 7CP20 1BA0 ...