AR-BC260 SETTING AND ADJUSTMENTS 8 - 8

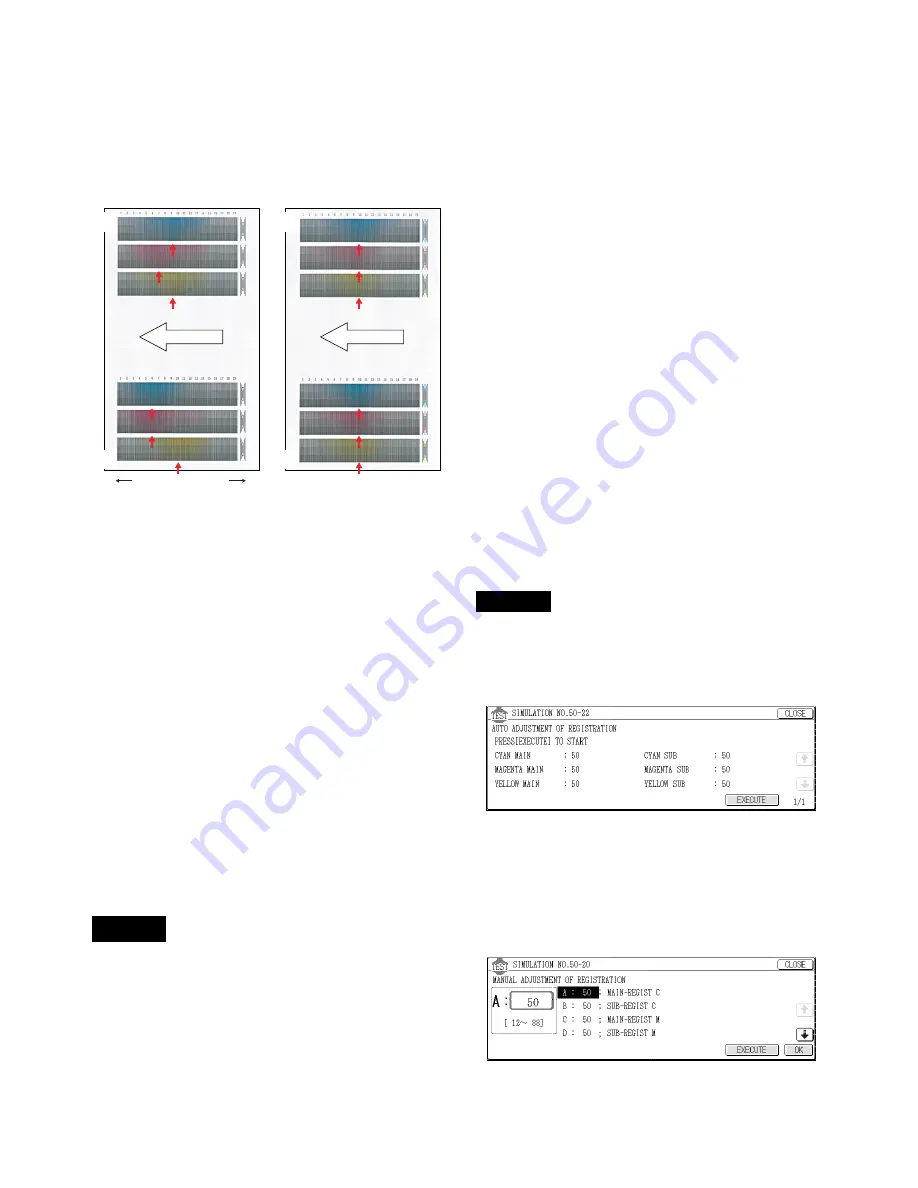

10) Check the printed image skew (distortion) pattern.

Compare the same color print pattern on the front frame side

with that on the rear frame side, and check that the difference

between the two highest-density areas is within 2 steps.

(Compare the same color print pattern on the front frame side

with that on the rear frame side. There is no need for the posi-

tions of the highest-density areas of the print color patterns of

all the colors to be aligned on a line. Compare only the same

color pattern positions.)

If the above conditions are not satisfied, remove the developing

unit on the left and turn the print engine image skew adjustment

screw on the front frame side.

To adjust the print engine image skew of Cyan, for example,

remove the Magenta developing unit. (To adjust the print engine

image skew of Yellow, however, this is not required.)

At that time, use SIM 7-1 to set DV CHECK DISABLE to Enable

and to disable the developing unit installation detection.

When the image pattern on the front frame side is skewed to the

right (arrow direction A) with the rear frame side as the reference,

turn the adjustment screw clockwise. When the image pattern is

skewed to the left (arrow direction B), turn the adjustment screw

counterclockwise.

When the adjustment screw is turned 1/4 rotation, the image posi-

tion is shifted by one dot.

Remark: The print engine image focus adjustment is performed

by changing the distance between the LED array unit

and the OPC drum.

The print engine image skew adjustment is performed

by changing the parallelism of the LED array unit for the

OPC drum.

If either of the two adjustments is performed, it may

affect the other adjustment due to the machine structure.

After completion of the above procedures, check that

both of the above two adjustments are satisfied.

There are two methods of the image registration adjustment: the

manual adjustment and the automatic adjustment. Either of them

uses the simulation.

This adjustment is required in the following cases:

• When the scanner (writing) unit is replaced.

• When the scanner (writing) unit is removed from the machine.

• When color image mis-resist is generated in the main scanning

direction.

• When color image mis-resist is generated in the sub scanning

direction.

• When installation or the installing place is changed.

• When maintenance is performed. (When the OPC drum, the

photoconductor cartridge, the transfer unit, or the transfer belt is

replaced.)

• When U2 trouble occurs.

• When ICU PWB is replaced.

• When EEPROM on ICU PWB is replaced.

Remark: Though SIM 50-22 is not performed under the following

conditions, the image registration adjustment is per-

formed automatically.

∗

When the toner cartridge is replaced.

∗

At every 8,000 copies (total of print quantity and copy quantity)

(When 8,000 copies is reached during a job, the machine stops

after completion of the job.)

If the set item AR of SIM 44-1 is set to OFF (Disable), the above

operation is not performed.

After setting the image registration to the best by SIM 50-20, when

the image registration adjustment is automatically performed, the

best-adjusted condition may be varied. To avoid this, set the item

AR of SIM 44-1 to OFF (Disable).

Note:

Before executing this adjustment, check that the following adjust-

ments have been properly completed.

∗

Print engine image focus adjustment (Scanner (writing) unit)

∗

Print engine image skew adjustment (Scanner (writing) unit)

∗

Image registration sensor adjustment

∗

SIM 48-6 FSM (Fuser roller speed) is set to the default.

Default setup of SIM 48-6 FSM (Fuser roller speed)

D: 80 (For paper of 420mm or shorter in the transport direction)

I: 85 (For paper of 420mm or longer in the transport direction)

J: 85

K: 70

This adjustment is used to perform the image registration adjust-

ment in the main scanning direction and in the sub scanning direc-

tion at the same time with the simulation.

1) Enter the SIM 50-22 mode.

SIM 50-22

2) Press the [EXECUTE] key.

The [EXECUTE] key is highlighted, and the image registration

automatic adjustment is started. After completion of the adjust-

ment, the [EXECUTE] key returns to the normal display.

The adjustment process status is indicated with (

∗

) mark. It

takes several minutes to complete the adjustment.

3) Enter the SIM 50-20 mode.

SIM 50-20

4) Select the A4 (11 x 8 1/2) size paper feed tray.

5) Press the [EXECUTE] key.

The image registration adjustment pattern is printed.

ADJ 4

Image registration adjustment

B

A

Improper adjustment

Proper adjustment

Rear

side

Paper exit side

Front

side

Rear

side

Front

side

Paper exit side

ADJ 4A

Image registration adjustment

(Auto adjustment)