Rostock MAX v2 Assembly Guide – 4thEd.

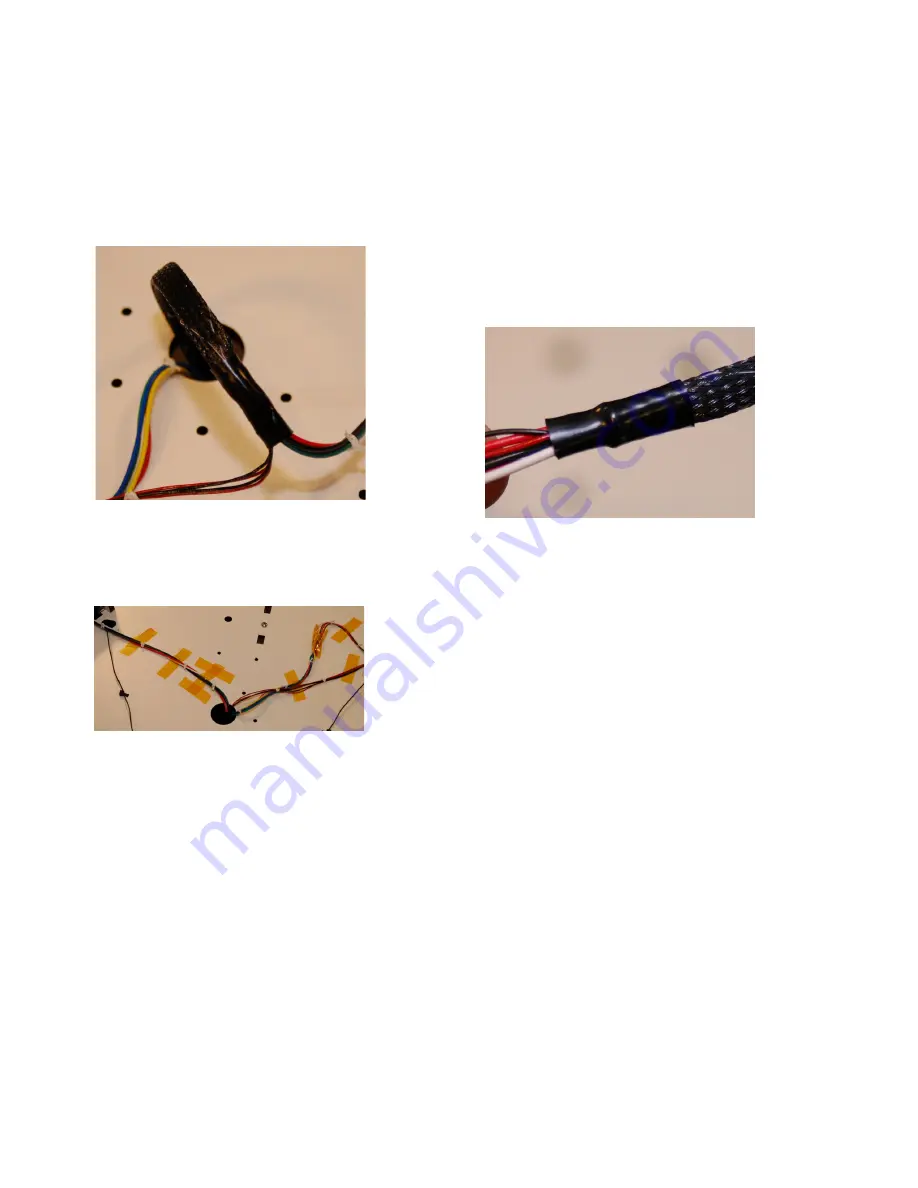

Using a hair dryer or heat gun, heat the tubing until it conforms to the loom & wires as shown

in Fig. 11.1-3. Keep the heat source moving around the tubing as it shrinks to get an even shrink all the

way around. You'll want to be careful to not melt the mesh, so don't leave your heat gun focused on

one spot too long.

Gently pull the mesh towards the end of the wire and add

another 1” piece of heat shrink to the end. (Pull the mesh

tightens it up and it lengthens as this happens.)

Once you've done that, take a few minutes to tape down the hot end and fan wiring as shown.

Note that the photos here show the “B” hot end wires.

For the “A” hot end wires, you'll have two each, red & black

26ga wires, one pair of white 26ga wires and one each red &

black 18ga wires.

11 – Installing the Hot End and Bowden Tube – 99

Fig. 11.1-3: Top end done.

Fig. 11.1-4: Heat shrink on the business end.

Fig. 11.1-5: Neat wiring!