Mach-DSP User’s Manual

Document Number: MACH-DSP-9021

Page 22

www.ScannerMAX.com

3.6

Scanner interface

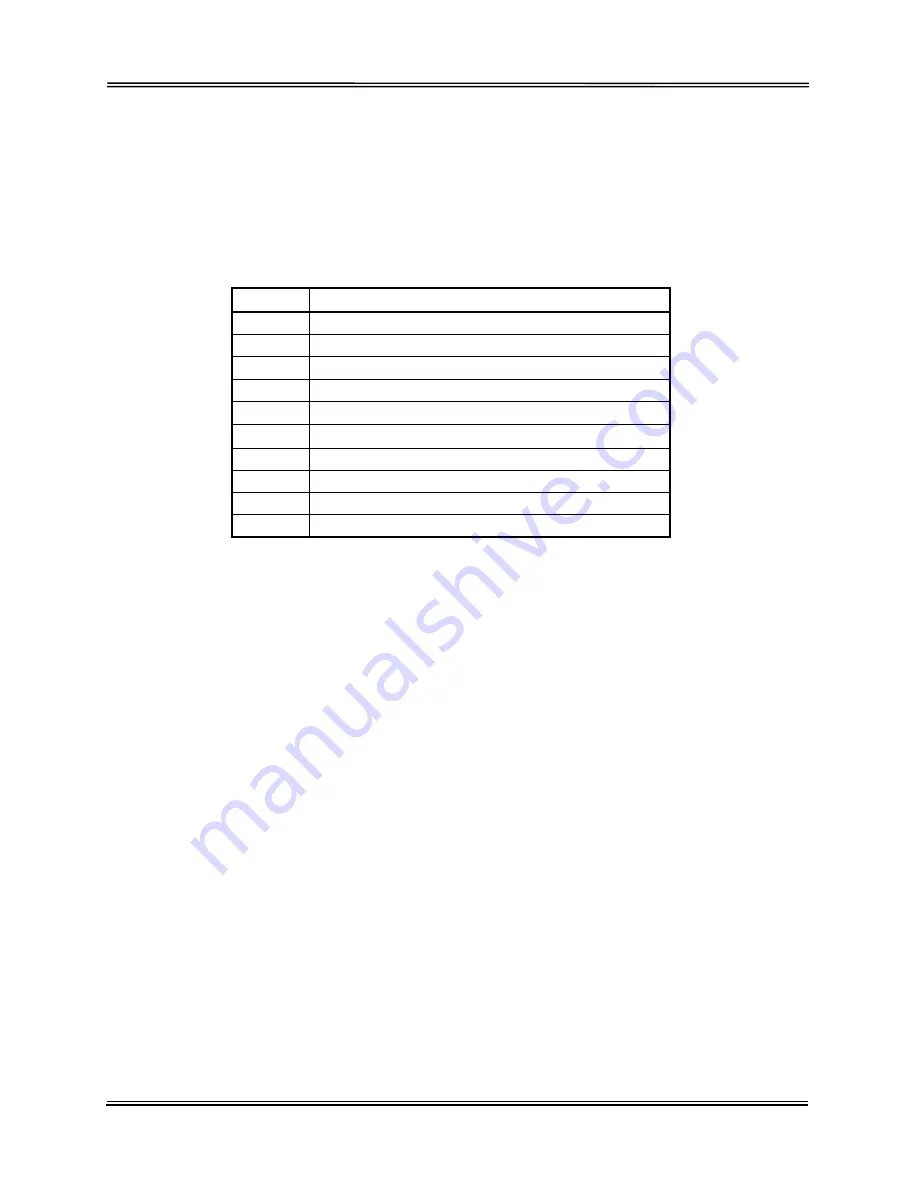

Each scanner is connected to the Mach-DSP through a single cable that provides both

the position sensor and motor drive wires. The connector pin functions are provided in

Table 3.6:

Table 3.6: Scanner Interface

Pin

Function

1

Position sensor photodiode current “B”

2

LED cathode drive (negative current)

3

Motor body / shield

4

Motor drive +

5

Motor drive -

6

Position sensor photodiode current “A”

7

Position sensor photodiode common

8

LED anode drive (ground)

9

Motor drive + (redundant)

10

Motor drive - (redundant)

Mating Connector Housing:

MOLEX Micro-Fit Jr: 0430251000

Mating Connector Pins:

0430300001 through 0430300012

Specified Wire Size:

AWG #20-#30, depending on pin type

Note that the LED drive on pin 2 presents a negative current instead of a positive

current, which is more common in the industry. This is because most often, the large

body of an LED is the positive terminal, and the small bond wire is driven with a

negative voltage. This means that the large body (“positive” contact) of the LED is more

sensitive to RF interference from walkie-talkies, cell phones and the like. Thus, by

driving the LED with a negative current, the largest portion of the LED (the body)

becomes grounded, thus this improves the RF immunity of the position sensor portion of

the scanner, and also improves signal-to-noise ratio of the position sensor, and of the

entire servo system.

Likewise, the Photodiode currents on pin 1 and 6 are expected to be positive currents,

not negative currents as are more common in the industry. However, unlike the LED

current drive, which is always negative, the Mach-DSP can be configured to expect

either a positive current or negative current on the photodiode input pins, depending on

how components are populated at the factory.