SECTION 5: C

OMMUNICATIONS

39

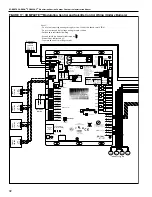

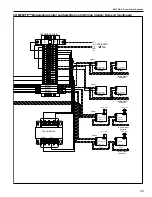

Each control board on the network must have a

unique MAC address. The IP address must be

unique on the Ethernet network. The default IP

address can be used or a custom IP address can be

assigned. In addition to these two addresses, the IP

network number must be set for each controller. Use

the touchscreen provided to set these values.

The touchscreen communicates between controllers

over an MS/TP network with network number 100.

This must not be changed.

The MS/TP network

number is important for the broadcasting of Outside

Air Temperature.

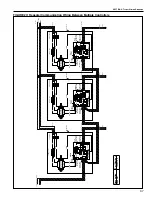

Create the MS/TP network between controllers.

. Access the controller you wish

to program through the touchscreen home menu.

for help.

Default IP Address

IP address: 192.168.168.x where x is the MAC

address

Subnet mask: 255.255.255.0

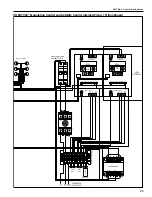

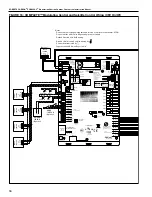

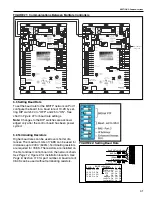

To set the MAC address on the controller, use the

rotary switches located just above the HOA switches

on the control board. Refer to the above photo. The

switches are for the 1's place and the 10's place

respectively.

Note:

Changes to the switches are recognized only

after power has been cycled to the control board. To

properly cycle power to the control board and touch-

screen, turn the circuit breaker located on the termi-

nal strip above the control board off for 10 seconds

before turning it back on. To use the

default

IP

address, ensure DIP switch 2 is in the

off

position.

Custom IP Address

Assign a custom IP address using the touchscreen

located on the central control panel provided. Open

the local Menu at the bottom right of the screen scroll

to the bottom, and select IP. This opens the IP menu.

IP can be reached on

Menu

IP

Enter an IP address in the

Assigned IP Address

field. Click save.

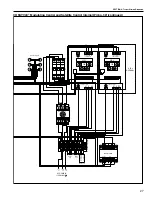

On the control board, turn DIP switch 2 on. All other

DIP switches should be off.

manual for help locating the DIP switch.

Cycle power to the control board. Allow the touch-

screen time to reload information from the board,

then navigate back to the IP menu. The

Current IP

Address

should now be populated with the assigned

address.

IP Network Number

Finally, set the IP network number to a value other

than 100 (i.e. 101). The IP network number must be

set for each controller with an Ethernet connection.

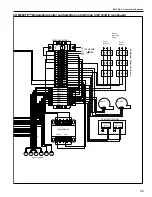

5.3 Integration into Building Management System

(BMS)

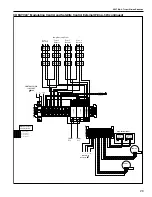

The controller (I/O Pro 812U) is capable of communi-

cating with a foreign BMS. Connection can be made

easily by connecting the controller to BMS by the 2-

Содержание CORAYVAC

Страница 2: ......

Страница 4: ......

Страница 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Страница 73: ...SECTION 9 TROUBLESHOOTING 69 FIGURE 28 VFD showing a fault sign FIGURE 29 VFD input power issue ...

Страница 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Страница 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Страница 79: ...SECTION 9 TROUBLESHOOTING 75 FIGURE 34 APS does not close within 60 seconds after VFD receives run command ...

Страница 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Страница 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Страница 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Страница 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

Страница 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Страница 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Страница 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Страница 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...

Страница 119: ...SECTION 14 THE ROBERTS GORDON CORAYVAC COMPLETE MODULATING HEATING CONTROL LIMITED WARRANTY 115 ...