ROBERTS GORDON

®

CORAYVAC

®

M

ODULATING

H

EATING

C

ONTROL

C

ONTROLLER

I

NSTALLATION

M

ANUAL

50

6.2.1 Acknowledge error message (Reset)

To acknowledge and reset the current error mes-

sage, you can either switch off the supply voltage or

press the STOP button. Error messages (a maximum

of four) are stored in parameter P-13.

6.2.2 Error Messages

The following table shows the Error messages list,

the possible causes and indicates corrective mea-

sures. Refer to the supplied VFD installation and

operation manual for more details or VFD trouble-

shooting.

Failure

Code

[hex]

View

Designation

Possible Cause

Notes

01

01-b

Braking chopper over

current

• Overcurrent braking

resistance

• Overcurrent in braking resistor

circuit.

• Check the wiring to the braking

resistance.

• Check the brake resistor value.

Make sure to adhere to mini-

mum resistance values.

02

0L-br

Thermal overload braking

resistance

• Braking resistance

overload

• Increase the deceleration time,

reduce the load's moment of

inertia, or connect additional

braking resistors in parallel.

• Make sure to adhere to mini-

mum resistance values.

03

0-I

Overcurrent motor

• Overcurrent at output

• Motor overload

• Overtemperature at

heat sink

• Short circuit / ground

fault

• Motor with constant speed:

Determine the overload or fault.

• Motor starts: The load stalled or

has seized. Check whether

there is a star/delta motor wir-

ing error.

• Motor accelerates/decelerates:

The excessively short accelera-

tion/deceleration time is requir-

ing too much power. If P-03 or

P-04 cannot be increased, a

more powerful variable fre-

quency drive is required.

• Cable fault between variable

frequency drive and motor.

04

It-trF

Thermal motor overload

• The DC1 variable fre-

quency drive was

switched off after

more than 100% of

the value set in P-08

was delivered for a

period of time

• Check whether the decimal

places are flashing (variable

frequency drive overloaded)

and either raise the accelera-

tion ramp (P-03) or reduce the

motor load.

• Make sure that the cable length

matches the variable fre-

quency drive specifications.

• Check the load mechanically in

order to make sure that it is

free, that nothing is getting

jammed or locked, and there

are no other mechanical faults.

Содержание CORAYVAC

Страница 2: ......

Страница 4: ......

Страница 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

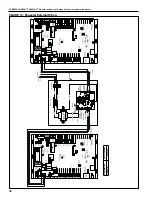

Страница 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Страница 73: ...SECTION 9 TROUBLESHOOTING 69 FIGURE 28 VFD showing a fault sign FIGURE 29 VFD input power issue ...

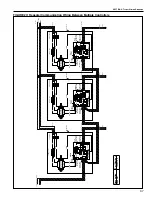

Страница 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Страница 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Страница 79: ...SECTION 9 TROUBLESHOOTING 75 FIGURE 34 APS does not close within 60 seconds after VFD receives run command ...

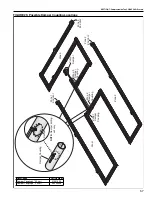

Страница 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Страница 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Страница 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Страница 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

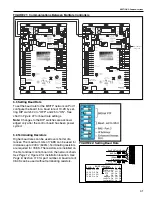

Страница 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Страница 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Страница 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Страница 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...

Страница 119: ...SECTION 14 THE ROBERTS GORDON CORAYVAC COMPLETE MODULATING HEATING CONTROL LIMITED WARRANTY 115 ...