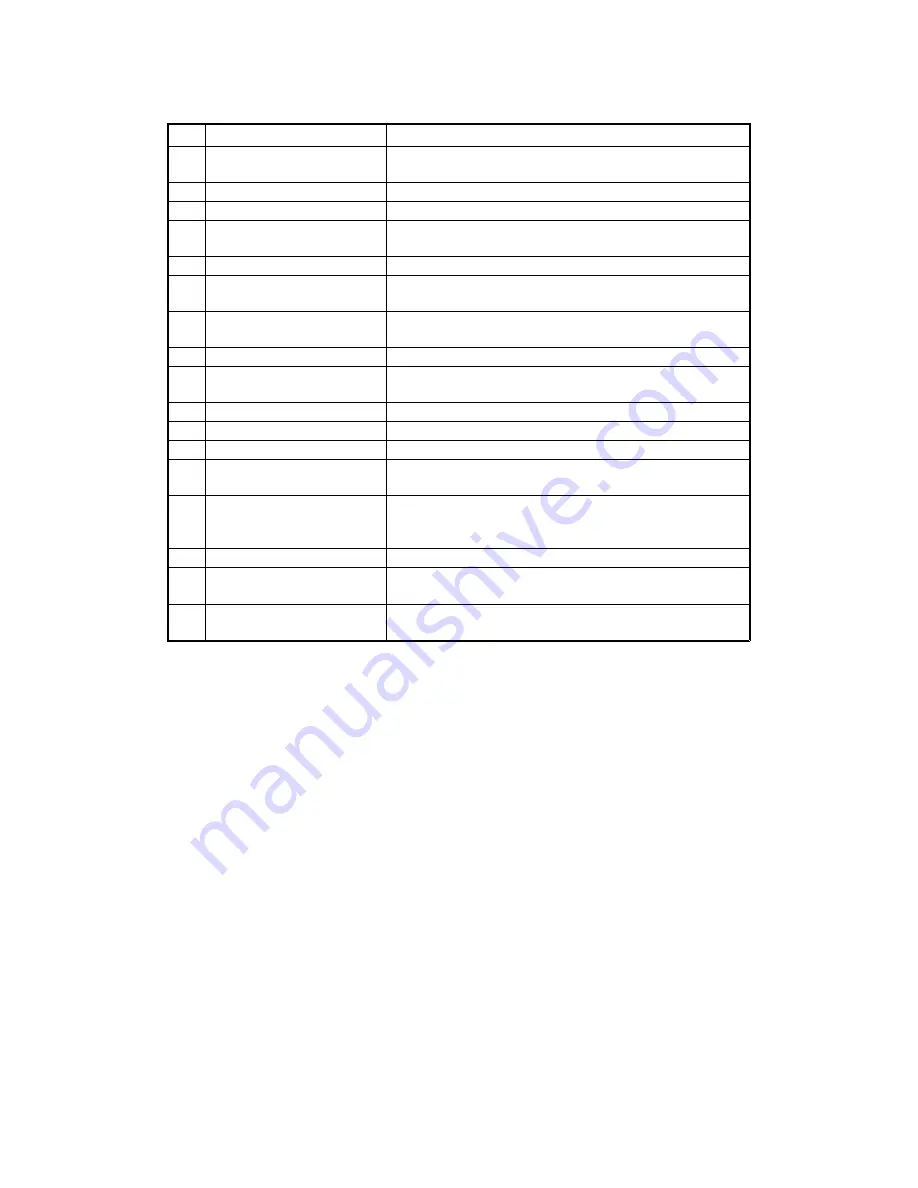

No.

Name

Description

9

Toner Supply Bar

This stirs up and transfers toner to the toner application

roller.

10

Toner Application Roller

This roller transfers toner to the development roller.

11

Development Roller

This roller applies toner to the latent image on the drum.

12

Platen Cover

This covers the original which was placed on the

exposure glass.

13

Exposure Glass

Book scanner reads the original on it.

14

CTM (Cleaning Toner

Magazine)

This consists of the toner cartridge, cleaning unit, used

toner tank, charge corona unit, and quenching lamp.

15

OPC Drum

The latent image is written to this Organic

Photoconductor Drum.

16

Hot Roller

Heat from this roller fuses the toner to the copy paper.

17

Cleaning Pad

This cleans up and spreads silicone oil on the surface

of the hot roller.

18

Hot Roller Strippers

These take the paper off the hot roller after fusing.

19

Paper Feed-out Rollers

These feed the paper out of the printer.

20

Fusing Pressure Roller

This applies pressure to the paper during fusing.

21

Transfer Roller

This applies a charge to the paper to pull the toner off

the drum and onto the copy paper.

22

Paper Feed Rollers (100

Sheet Cassette)

These pick up the top sheet of paper from the stack in

the optional 100 sheet cassette and feed it into the

printer.

23

Registration Roller

This carries out the registration process.

24

Paper Feed Pressure

Rollers

These feed paper from the cassette or bypass feed slot

into the printer.

25

Paper Feed Rollers

These pick up the top sheet of paper from the stack in

the cassette and feed it into the printer.

May 22nd, 1995

OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

1-7