Operative Instructions

19

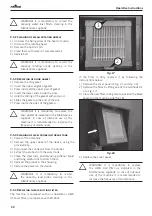

6.1.4 N.T.T. (No Touch Technology)

Wash programs can be started using three no touch

sensors as well as using the standard control panel.

The symbol on the sensor is the same as the symbol on

the control panel and indicates, for both functions, the

related kind of program.

An infrared sensor performs the same function as the

pedal control: it can be used to open and close the

wash chamber door.

Use of no touch sensor on machine is part of the

cleanliness and hygiene philosophy that the company

has been pursuing for years, making it easier and

cleaner for operators to use the machine. Generally

the items to be washed are carried to and placed in

the machine using disposable gloves. These gloves

might get dirty during these tasks. The no touch sensor

permit the wash cycle to start without the need for the

operator to remove the gloves.

Fig. 8

The sequence we recommend for properly using the

appliance is as follows:

1) Once in front of the machine with the items to be

washed, use the pedal control to open the door;

2) Place the items on the support as indicated in the

support's instructions;

3) Start the chosen wash cycle by passing your hand in

front of the sensor;

4) When the wash cycle is finished the machine will

open automatically the door;

5) Remove the items that have been cleaned;

6) Close the door activating the infrared sensor or the

pedal.

7 Using the machine

Before starting the machine, the operator in charge

must have read and understood this whole manual,

in particular the information given in section «3 Safety

and prevention».

Furthermore, before starting work, check that the

machine is in order and that all parts subject to wear

and deterioration are fully efficient.

7.1 Commissioning instructions

These control operations (reported below) are

performed to check if the machine works properly and

should be performed when the machine installation is

completed.

1) Open the tap that supplies water to the machine.

a

WARNING! The water should NOT flow into

the chamber; otherwise the water loading

solenoid valves are dirty or blocked due to

long storage in the warehouse and therefore

they must be cleaned.

a

WARNING! Check that there are no water

leaks in the pipe fittings.

2) Check that the suction tubes (located in the lower

part of the machine) within the corresponding tanks

containing the liquids provided (limescale remover

and detergent), are correctly inserted.

3) Using the main circuit breaker, supply power to the

machine.

4) Check that the water supply flexible hoses are

properly connected.

5) At the beginning of the first cycle check the level

probes of the liquid suction tubes (limescale

remover and detergent): pull one tube at a time

out of the container and check if the corresponding

alarm flashes on the display, indicating the need for

liquid refilling.

6) Check if the peristaltic pumps correctly suck

washing liquids. To do this, check that the liquid

rises along the tube connected to them.

7) If a machine with automatic door has been installed,

open the door and slightly grease the three sides of

the basin seal (that may have dried due to a long

warehouse storage) and the corresponding door

parts on which the seal will lean when the door

is shut. Open and close the door a dozen times,

helping the travel by applying a slight force with

both hands at the two sides of the door.

7.2 Before use

The bedpan washer can be used for cleaning and

disinfecting:

- urinals;

- commodes;

- urology containers;

- kidney-shaped basins;

Содержание DVS

Страница 40: ...Operative Instructions 40 Notes ...

Страница 41: ...Operative Instructions 41 Notes ...

Страница 42: ...Operative Instructions 42 Notes ...