Operative Instructions

15

laboratories, medical practices and environments

connected to the public electricity grid.

The high-frequency (HF) energy emissions of

the machine are so small that interferences with

electrotechnical equipment in the immediate vicinity

are not likely.

The optimal positioning floor must be made of

concrete, wood or ceramic tiles. In case of machine

operation on floors made of synthetic materials,

the relative humidity must be 30% to minimise the

likelihood of electrostatic discharges.

5.2 Water connection

)

CAUTION! The water in the wash chamber is

not drinkable.

The quality of the water used must be compatible with

the manufacturing materials of the machine, with the

chemicals and with the process needs in the various

stages of the procedure.

To have good washing results, the water must be soft

and low in limestone. With hard water white patinas

deposit on the objects to be treated and on the walls of

the wash chamber.

For the correct operation of the machine, the water

inside the washing chamber must have a maximum

hardness of 3.03 mmol/l CaCO

3

(17.80°DH / 30°fH).

If the installation site does not have water with the

required specification, it is necessary to install an

external softener.

The water used in all the washing stages should be

of drinking quality according to the “Guidelines for

drinking-water quality, 4th edition” published by the

WHO. A high iron content can cause rust on the load

and in the special washing machine. If industrial water

contains a higher amount of chlorides than 100 mg/l,

the risk of corrosion significantly increases.

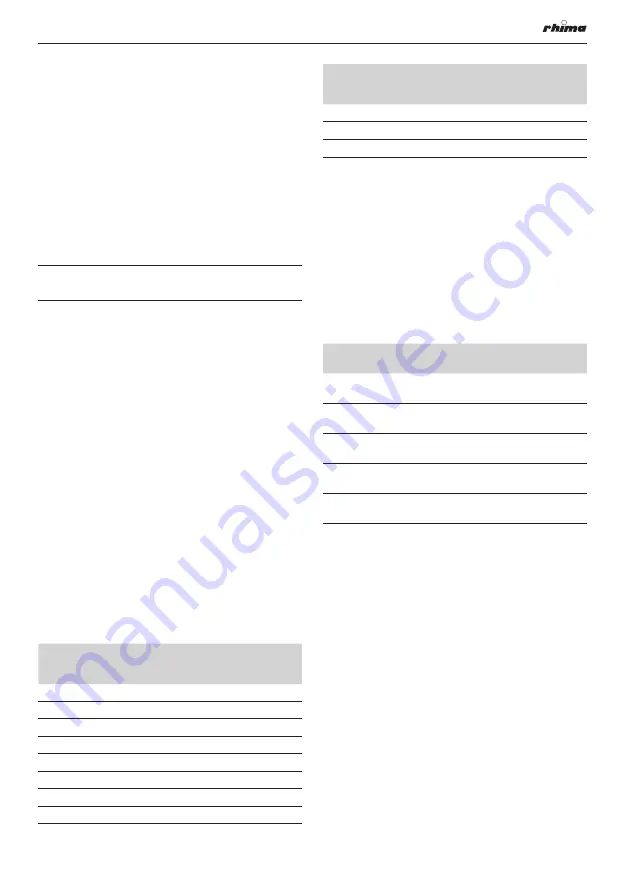

Water hardness conversion table:

French

degrees

[°fH]

CaCO

3

[mmol/l]

German

degrees

[°DH]

CaCO

3

[PPM]

0-10

0-1.01

0-5.60

0-100

11-15

111-1.51

6.16-8.40

110-150

16-20

1.61-2.02

8.96-11.20

160-200

21-25

2.12-2.52 11.76-14.00

210-250

26-30

2.62-3.03 14.56-17.80

260-300

31-35

0-5.60

17.36-19.60

310-350

36-40

6.16-8.40 20.16-22.40

360-400

41-45

8.96-11.20 22.96-25.20

410-450

French

degrees

[°fH]

CaCO

3

[mmol/l]

German

degrees

[°DH]

CaCO

3

[PPM]

46-50

11.76-14.00 25.76-28.00

460-500

51-55

14.56-17.80 28.56-30.80

510-550

56-60

5.66-6.06 31.36-33.60

560-600

The special washing and disinfecting machine is

standard prepared for connection to cold and hot

water. Connect the flow pipes to the shut-off valves for

cold and hot water.

- The machine must be connected to the water mains

in accordance with current regulations.

- If the water supply of the device has not been used for

a long time, or if it is used for the first time, purge it by

draining the water into a container or into a drain for

a few minutes in order to remove any impurities, air

bubbles and/or whatever may damage the machine

and clog its filters.

Cold

water

Hot

water

Min.

temperature

5°C

41°F

45°C

113°F

Max.

temperature

20°C

68°F

60°C

140°F

Recommended

flow pressure

300 kPa

43 PSIG

300 kPa

43 PSIG

Min. flow

pressure

170 kPa

25 PSIG

170 kPa

25 PSIG

Max. flow

pressure

600 kPa

87 PSIG

600 kPa

87 PSIG

- Connect the cold and hot water hoses exiting the

machine with their respective network connections,

as shown on the Technical Specifications (see pg. 2).

It will be the responsibility of the installer to make

sure that the temperature of the cold water supply

is correct, otherwise proper washing of materials

cannot be ensured. The connections for cold and

hot water must not feed any equipment other than

the bedpan washer. During the washing cycle, this

is necessary to prevent the subdivision of the water

supply with other users, thus leading to a substantial

increase in the time required to fill the chamber (in

this case an alarm will be triggered to alert the user

that the maximum time allowed for water loading is

exceeded).

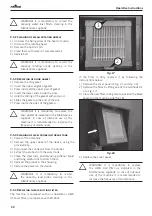

- Connect the flexible hoses to the machine valves

positioned in view at the back, making sure to connect

them correctly based on the sales configuration.

- Make sure to connect the water flexible hoses in the

positions shown in Fig. 7.

Содержание DVS

Страница 40: ...Operative Instructions 40 Notes ...

Страница 41: ...Operative Instructions 41 Notes ...

Страница 42: ...Operative Instructions 42 Notes ...