CDJ-800MK2

100

1

2

3

4

1

2

3

4

C

D

F

A

B

E

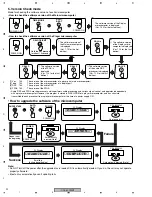

Player (3/4)

Sites

Waveforms

Points to be checked

Causes & Measures to be taken

Remarks

The error rate measured in Test Operation mode of Service mode is high.

z

To which the cause is attributed, disc or

player, must be judged first.

Visually check the disc for stains on the

recording surface.

If the disc is clearly stained, replace it with a

clean CD.

x

Using the disc that produced a high error rate,

measure an error rate at addresses in a different

area.

If the error rate at addresses in a different area is

not high, the CD is defective. Replace it with a

high-quality CD.

If the error rates at addresses in different areas

on the whole disc are high, proceed to Step

3

.

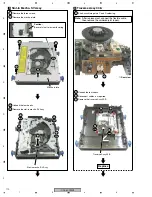

Pickup Assy

c

Check if shavings or dirt are attached to the

pickup lens.

Clean the lens.

Player

v

Check if the TM Assy (servo mechanism) is

securely attached.

Player

b

Check if the loading mechanism SV Assy is

securely attached.

Pickup Assy

n

Check if any foreign object is on the spindle

table.

Remove the foreign object.

Pickup Assy

m

Check if any foreign object is attached to the

magnet section of the Pickup Assy.

Remove the foreign object.

Player

MAIN Assy

, , ,

,

Check the S-curve, TE, RFO, and AGCRF

levels in Service mode.

See "Failure judgment of the Pickup Assy" for

details.

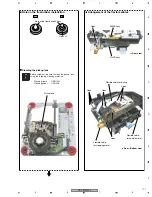

The LD is not turned on after entering Test Operation mode of Service mode.

RLYB Assy

z

Visually check if the LD short-circuit switch

(S1101) remains closed.

Set the LD short-circuit switch to OPEN.

MAIN Assy

x

Check that Pins 41 and 42 on the Servo DSP

(IC101) are open or short-circuited.

Player

c

Check if the FFC cable that connects the

Pickup and the RLYB Assys is securely

connected to the Pickup Assy, if the conductor

side is defective, and if there is any cable

breakage. Also check for loose connection of

connectors.

If the symptom is ameliorated by replacement of

the FFC cable, the defective cable is the cause.

MAIN Assy

v

Check if the R101 to R105 or Q105 are

missing.

MAIN Assy

b

Check if the FFC cable that connects the

RLYB and MAIN Assys is firmly connected to

CN101.

The pickup lens does not move up or down after entering Test Operation mode of Service mode.

Player

z

Check if the FFC cable that connects the TM

and the RLYB Assy is securely connected to the

Pickup Assy, if the conductor side is defective, or

if there is any cable breakage. Also check for

loose connection of connectors.

If the symptom is ameliorated by replacement of

the FFC cable, the defective cable is the cause.

Pickup Assy

x

Check if the resistance of the focus coil is too

large or if the focus coil is broken, using Service

mode.

See "Failure judgment of the Pickup Assy" for

details.

MAIN Assy

c

Check if the 7 V power is supplied to Pin 32 of

IC102.

MAIN Assy

MAIN Assy

v

Check if the signal output from the FOO

terminal on the MAIN Assy oscillates centered

around 1.65 V.

LD short-circuit switch

1

2

8

11

9

Содержание CDJ-800MK2

Страница 27: ...CDJ 800MK2 27 5 6 7 8 5 6 7 8 C D F A B E MODE MODE 3 3 A 27 24 26 19 36 ...

Страница 29: ...CDJ 800MK2 29 5 6 7 8 5 6 7 8 C D F A B E Data PANEL DATA Digital A 2 3 3 3 A 3 3 A 23 ...

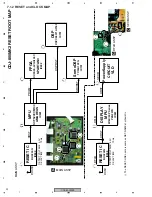

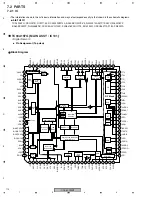

Страница 119: ...CDJ 800MK2 119 5 6 7 8 5 6 7 8 C D F A B E SCF5249LAG140 MAIN ASSY IC301 32 bit RISC MPU Block Diagram ...

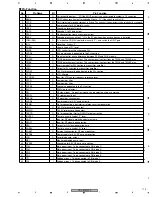

Страница 130: ...CDJ 800MK2 130 1 2 3 4 1 2 3 4 C D F A B E Pin Function ...

Страница 135: ...CDJ 800MK2 135 5 6 7 8 5 6 7 8 C D F A B E Pin Function ...

Страница 138: ...CDJ 800MK2 138 1 2 3 4 1 2 3 4 C D F A B E PE8001A MAIN ASSY IC702 DAC IC Pin Arrangement Top view Block Diagram ...

Страница 139: ...CDJ 800MK2 139 5 6 7 8 5 6 7 8 C D F A B E Pin Function ...

Страница 143: ...CDJ 800MK2 143 5 6 7 8 5 6 7 8 C D F A B E ...

Страница 153: ...CDJ 800 7 5 6 7 8 5 6 7 8 C D F A B E ...

Страница 174: ...CDJ 800 28 1 2 3 4 1 2 3 4 C D F A B E 3 7 JFLB SLDB and JOGB ASSYS I JFLB ASSY DWG1565 I CN500 F ...

Страница 180: ...CDJ 800 34 1 2 3 4 1 2 3 4 C D F A B E ...

Страница 200: ...CDJ 800 54 1 2 3 4 1 2 3 4 C D F A B E 6 ADJUSTMENT There is no information to be shown in this chapter ...