User Manual – ePX 200

OptiPro Systems, LLC.

Page 40 of 60

Last Modified: 7/30/2014

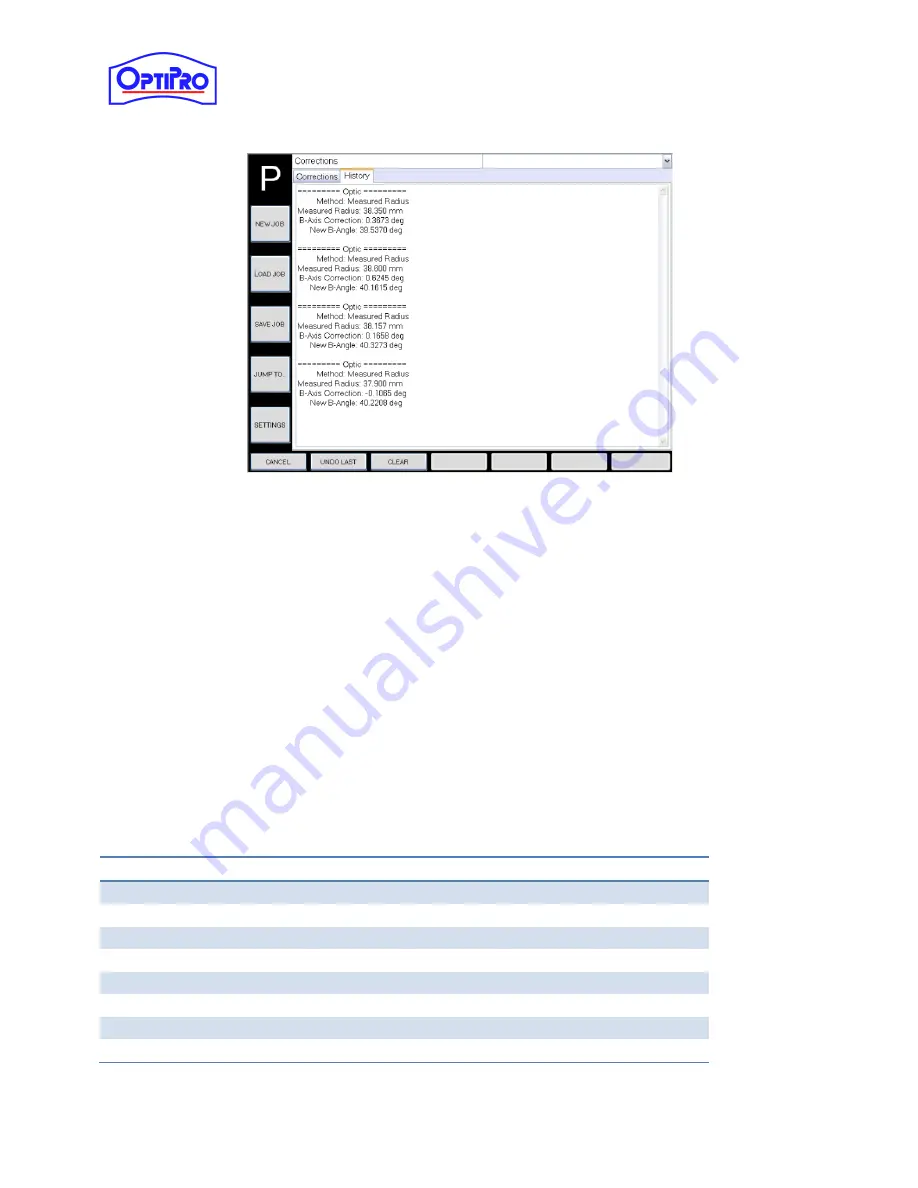

Figure 7-21: Corrections History

Tapping the [History] tab at the top of the Corrections screen (Figure 7-16) will bring up the correction

history for the currently loaded job. This allows the technician to keep track of the adjustments that

have been made as the job progresses. Additionally the technician can remove the last correction should

an over or under correction occur. With experience the technician will use this feature quite often.

7.9

Creating the Tram Check Program

Upper and lower tram ball programs are installed with on every new ePX. Should the tram programs

become lost or deleted, Table 7-4 and Table 7-5 will walk the technician through the Tram Programming

procedure.

Starting a tram check follows the same procedure as creating a new job. The required parameters for

the Job Setup screen are summarized in Table 7-4.

These parameters are meant to provide a safe

starting point for the tram check, not final values.

Table 7-4: Job Setup screen parameters

Parameter

Value

Shape

Convex

Radius of Curvature

12.7

Lens Diameter

25.4

Reception Height

Measured Offline, Top of the Schunk to Apex of the Ball

Outside Diameter

25.4

Inside Hole Diameter

0

Initial Pad Thickness

0

Polishing Tool Length

50