9

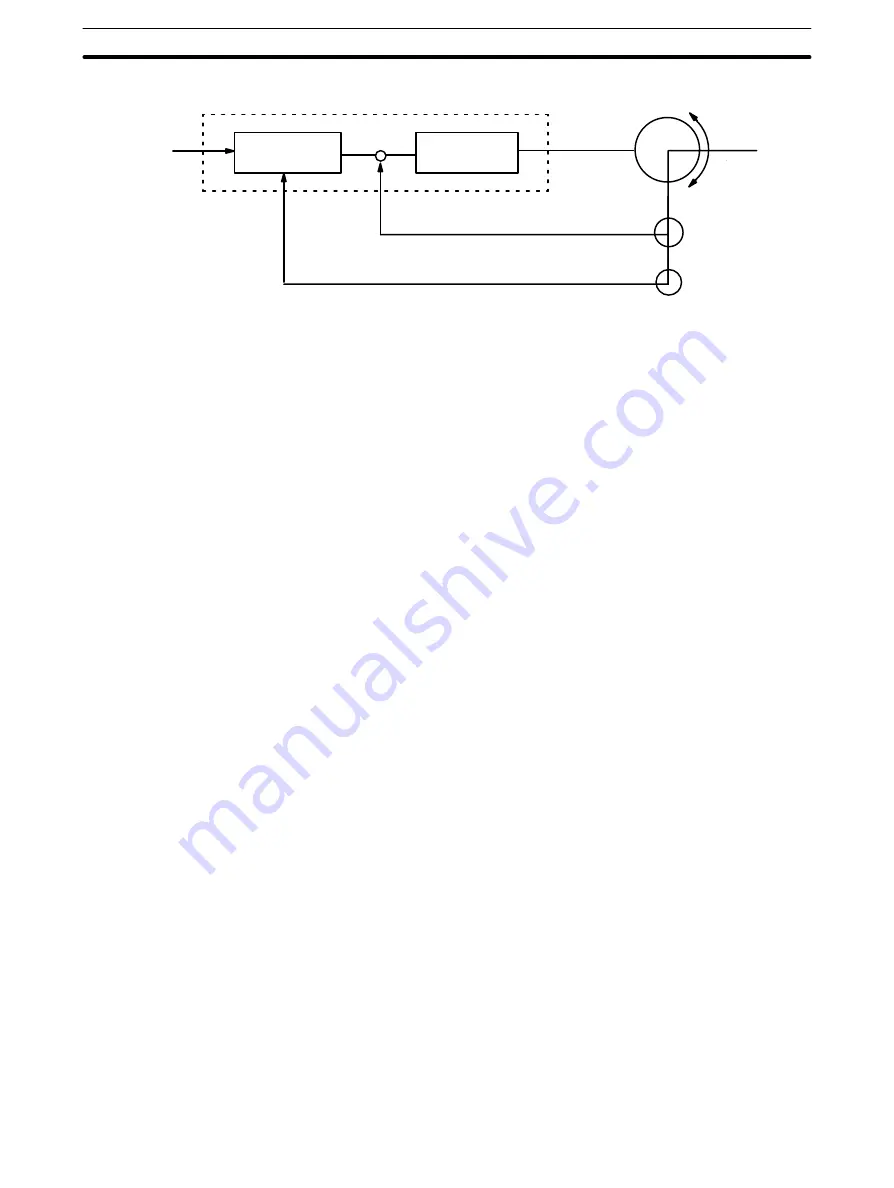

Rotary encoder

Tachogenerator

Servomotor driver

Servomotor

Position output

Error counter

Power amplifier

Position feedback (feedback pulses)

Speed feedback

Target position

1, 2, 3... 1.

First, the target position is transmitted to the error counter in units of en-

coder pulses. The servomotor driver must be able to handle digital input.

2.

The motor rotates at a speed corresponding to the speed voltage. The

rotary encoder connected to the motor axis rotates in sync with the mo-

tor, generates feedback pulses, and decrements the error counter.

3.

Consequently, the encoder rotation is equivalent to the target position,

and the motor stops rotating when the error counter count and the

speed voltage become zero.

4.

While the motor is stopped, the rotary encoder constantly maintains the

stopped position through correction. In the event that the motor axis

moves slightly, the error counter receives a feedback pulse from the

rotary encoder, causing a rotation voltage to be emitted in the reverse

direction from which the rotary encoder moved. This makes the motor

rotate toward its original position. This operation is called servolock or

servoclamp.

5.

In order to execute positioning with acceleration and deceleration, target

positions are set consecutively in the error counter for processing.

6.

The target position becomes the count for the error counter and controls

the motor by conversion to a speed voltage for the servomotor driver.

The position thus equals the total count of target positions and the

speed will depend on the target position per unit time.

Positioning System Principles