8

Positioning pulse

1 2 n

Positioning output

Angle of

rotation

Angle of rotation

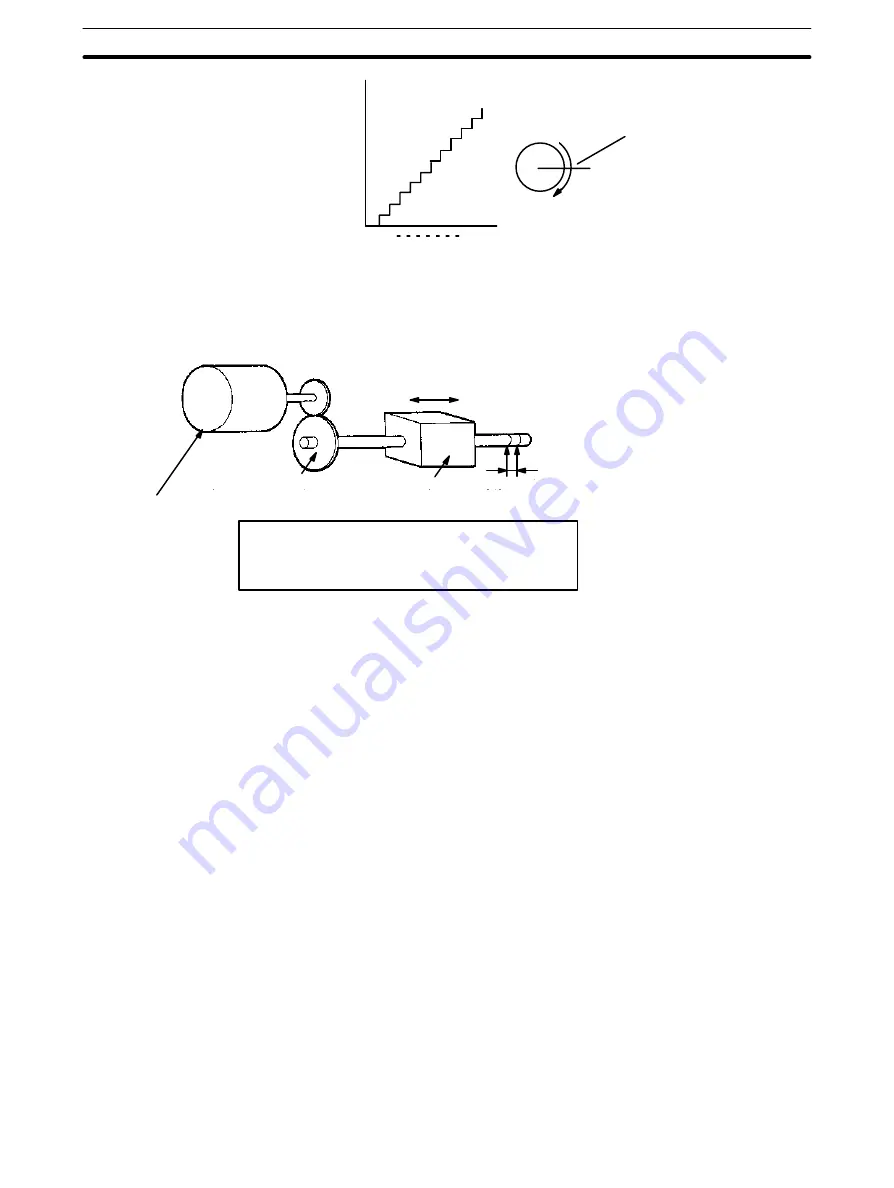

The following diagram and parameters illustrate a simplified positioning sys-

tem.

P

Stepping motor

Reduction gear

Object being

positioned

M: Reduction ratio

P: Feed screw pitch (mm/revolution)

V: Feed velocity of object being positioned (mm/s)

S

: Stepping angle per pulse (degree/pulse)

M

V

Feed screw pitch

S

The positioning accuracy in mm/pulse is computed as follows:

Positioning precision = P/(pulses per revolution x M)

= P/((360/S) x M))

= (P x S)/(360 x M)

The required pulse frequency from the Unit in pulses per second is computed

as follows:

Pulse frequency = V/Positioning precision

= (360 x M x V)/(P x S)

The required number of pulses to feed an object by a distance L (in mm) is

computed as follows:

Number of pulses = L/Positioning precision

= (360 x M x L)/(P x S)

1–5–2

Semiclosed-loop System

When the Position Control Unit is used in a semiclosed-loop system, the sys-

tem supplies feedback which is used to compensate for any discrepancy be-

tween target values and actual values in position or speed. This system de-

tects motor rotation amounts, for example, computes the error between the

target value and actual movement value, and zeroes the error through feed-

back. The diagram below illustrates the basic configuration of a semi-

closed-loop system.

Simplified Positioning

System Design

Positioning System Principles