74

www.climacoolcorp.com

Basket Strainers

Maintenance

Basket strainers require little monitoring once they are

properly installed. The pressure differential across the strainer

should be checked periodically to determine if the screen

needs to be cleaned or replaced. If the pressure differential

goes unchecked and the screen becomes completely clogged,

the screen will break and require replacing .

Note:

Strainer

screens are not designed to withstand the same pressure

ratings as the housings . If the basket becomes completely

clogged, it will be exposed to the same pressure as the

housing . In most cases, this will cause the basket to fail and

potentially damage downstream equipment .

Regular maintenance involves:

•

Periodically checking for leaks

•

Timely cleaning or replacement of screen

During normal use, the basket will become clogged

with foreign matter, causing the differential pressure to

increase. Once the differential pressure has increased to

an unacceptable value, typically by 5 psi to 10 psi, it is time

to clean or replace the screen . It is not advisable to let the

differential pressure increase by 20 psi. This may cause the

screen to fail and possibly damage downstream equipment .

A convenient and safe way to determine when the screen

needs to be replaced is to install pressure gauges on

the inlet and outlet sides of the strainer . The maximum

acceptable pressure drop across the strainer will indicate

when the screen needs to be replaced . Screen size and

construction determine the maximum pressure drop that

a strainer screen can withstand . Please consult factory for

exact pressure ratings .

Strainer Element Cleaning

Before removing the cover of the basket strainer, the

pressure inside the vessel must be reduced to atmospheric

via suction or venting . Failure to do so may result in serious

bodily injury .

1 .

Isolate the basket strainer by closing the inlet and outlet

valve connections on either side of the basket strainer .

2 .

Open vent or drain plug to relieve pressure inside the

basket strainer. Drain fluid up to screen seat level.

3 .

Once pressure is relieved, remove the cover .

4 .

Remove baskets and clean . Avoid banging or hitting the

screen to remove stubborn debris .

5 .

Inspect basket and cover gasket for damage . If either is

damaged, replace . Always ensure there is a spare gasket

and basket on hand prior to maintenance .

6 .

Remove any debris or sludge from within the basket

strainer .

7 .

Replace clean basket into its original position, enrusing

it is squarely positioned on the screen seat .

8 .

Replace cover gasket and replace and tighten cover .

Follow the Start-up precedure outlines within the Operation

Instructions .

Содержание CLIMACOOL UCR 30

Страница 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Страница 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Страница 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

Страница 41: ...39 www climacoolcorp com Condenser Layout for RC1 007A H24 and RC1 008A H24 1 Row 2 Fan 1140RPM...

Страница 42: ...40 www climacoolcorp com Condenser Layout for RC2 019A 026A and 31A H48 and RC2 038A H44 2 Row 4 Fan 1140RPM...

Страница 43: ...41 www climacoolcorp com Condenser Layout for RC2 018A X48 RC2 026A X40 and RC2 032A X44 2 Row 4 Fan 830 RPM...

Страница 47: ...45 www climacoolcorp com 45 www climacoolcorp com Condenser Layout for RC2 048A Q82 2 Row 8 Fan 540RPM...

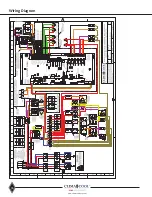

Страница 78: ...76 www climacoolcorp com Wiring Diagram...

Страница 79: ...77 www climacoolcorp com Wiring Diagram...

Страница 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Страница 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...