34

www.climacoolcorp.com

Head Pressure Control Valve Operation (LAC-10)

Brazing Procedures for Head Pressure

Control Valve

Any of the commonly used brazing alloys for high side

usage are satisfactory, however, when soldering or brazing,

it is very important that the internal parts be protected

by wrapping the valve with a WET cloth to keep the body

temperature below 250°F for the LAC . Also, when using high

temperature solders, the torch tip should be large enough to

avoid prolonged heating of the copper connections . Always

direct the flame away from the valve body. The remote bulb

is intended to be mounted to sense outside ambient air

temperature . Do not mount to any refrigerant line .

CAUTION: Inert gases must be added to the system

carefully through a pressure regulator. Unregulated gas

pressure can seriously damage the system and endanger

human life. Never use oxygen or explosive gases.

The table below lists the maximum values each valve can

withstand without damage . Precautions must be taken to

keep test or operating pressures below these values .

Table 7

Type Valve

Maximum Rated Pressure PSIG

LAC-10

680

Determining Amount of Charge

When “refrigerant side” head pressure control is utilized on

a system, one of the most important factors is determining

the total system refrigerant charge . While on most

packaged units the amount of charge is listed on the unit,

the required charge for a field built-up system cannot be

listed by the manufacturer . Charge is usually added when

the system is started up until “proper” system performance

is reached, however, if the system is to function properly

year-round,

the correct amount of extra charge must

be calculated ahead of time . The project submittal

includes a total refrigerant charge calculation as well . It is

recommended to charge no more than 65% of the listed

refrigerant charge prior to startup and have the remaining

refrigerant charge on site that can be trimmed as needed

during startup .

Completely Flooded Condenser

The easiest method is to calculate the

volume

of the

condenser coil and then use the density factor of the

refrigerant shown in Table 8, page 34, to figure the pounds

of refrigerant necessary to

completely

flood the condenser

coil at the appropriate ambient . The factors involved in

calculating the extra pounds of refrigerant are:

1 .

Length of tubing and return bends in condenser

2 .

Minimum ambient temperature at which systems will be

required to function

3 .

Tubing size and wall thickness

4 .

Refrigerant

The primary point to remember in selecting the proper

density factor is that when the liquid drain valve LAC is

throttling, the refrigerant temperature will be at the same

temperature as the ambient .

Example:

Calculate the extra refrigerant charge necessary

for a refrigerant R-410A, roof mounted remote condenser

(40°F evaporator and a minimum condensing temperature

of 90°F) with compressor unloading to 50% of full

compressor capacity . To determine the equivalent length of

tubing in a condenser, proceed as follows: First, count the

number of tubes and multiply this by their length .

Example:

150 tubes x 7 .55 feet = 1132 .5 feet

Next, count the return bends and multiply them by the

factor shown in Table 8 .

Example:

150 bends x .250 for 1/2 inch bends = 37 .5 feet

Then add this 37 .5 feet to the 1132 .5 feet for a total of

1170 feet

The system uses a 30 hp condensing unit with a condenser

coil containing 1170 equivalent feet of 1/2 inch tubing tubes

and return bends . Assume a design temperature of minus

20°F minimum ambient. From Table 8, find the density factor

necessary to calculate the pounds of extra refrigerant to

completely

flood the condenser at minus 20°F: 1170 feet x

.102 pounds/foot = 119 pounds .

Partially Flooded Condenser

On many systems it is not necessary to

completely

flood the

condenser to maintain sufficient operating head pressure

(equivalent to approximately 90°F condensing temperature)

because of a milder climate . Therefore, a second method is

available . The additional information found in Tables 9 and 10

can be used to figure more closely the charge necessary to

properly flood the condenser for sufficient head pressure at

various minimum ambient temperatures . (The multipliers are

applied to the extra refrigerant charge that was calculated in

the method to

completely

flood the condenser).

Example:

The example calls for a compressor equipped

with capacity unloading at roughly 50% using hot gas

bypass/combination liquid injection circuits . Since the chiller

controller will likely call for unloading during low ambient,

this must be taken into consideration . This is necessary

Содержание CLIMACOOL UCR 30

Страница 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Страница 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Страница 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

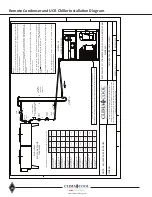

Страница 41: ...39 www climacoolcorp com Condenser Layout for RC1 007A H24 and RC1 008A H24 1 Row 2 Fan 1140RPM...

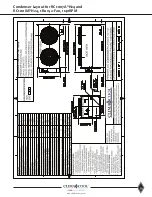

Страница 42: ...40 www climacoolcorp com Condenser Layout for RC2 019A 026A and 31A H48 and RC2 038A H44 2 Row 4 Fan 1140RPM...

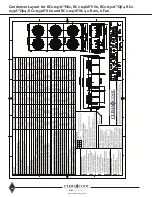

Страница 43: ...41 www climacoolcorp com Condenser Layout for RC2 018A X48 RC2 026A X40 and RC2 032A X44 2 Row 4 Fan 830 RPM...

Страница 47: ...45 www climacoolcorp com 45 www climacoolcorp com Condenser Layout for RC2 048A Q82 2 Row 8 Fan 540RPM...

Страница 78: ...76 www climacoolcorp com Wiring Diagram...

Страница 79: ...77 www climacoolcorp com Wiring Diagram...

Страница 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Страница 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...