14

www.climacoolcorp.com

Unit Installation

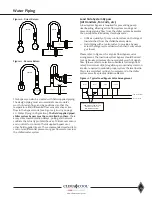

Inspect the pipe ends to ensure they are free from any

indentations, projections, roll marks or other harmful

surface defects such as loose paint, scale, dirt, chips,

grease and rust . Inspect the grooved coupling gasket for

any defects . Apply a thin layer of silicone or other non-

petroleum lubricant to the sealing lips of the gasket as well

as to the exterior of the gasket . Install gaskets on the pipe

ends of one of the two modules to be mated .

Be sure the

gasket is completely on the pipe to avoid damage in the

next step.

Move the second module into position and line

up the piping . Ensure the operator is maintaining alignment

for any additional modules to be added . When pipe ends

are aligned, slide the gasket over the ends and center it

between the grooves . No part of the gasket should protrude

into the groove of either pipe end . Place the coupling halves

over the gasket and make sure that the coupling keys

(the part that goes into the groove) are engaged into the

grooves . Insert the bolts and install nuts to hand tighten .

Ensure the oval neck of the bolt engages into the bolt hole

of the housing .

Tighten nuts alternately and equally until

the bolt pads meet and make metal to metal contact.

Tighten nuts by another quarter to half turn to make sure

the nuts and bolts are snug and secure . The use of a torque

wrench is usually not required .

Uneven tightening of bolts

may cause the gasket to be pinched resulting in immediate

or delayed leaks.

Header Insulation

Chilled water piping is pre-insulated on each module

at the factory with 3/4” closed cell insulation. After

bolting all modules together and leak testing, the entire

coupling connection will need to be insulated by the

installing contractor .

Sound Attenuation Panels and Gasket

Attenuation panels are enclosures made of 18 gauge

galvanized steel with powder coat paint finish and fiberglass

insulation . Field Installed panel package includes one (1)

upper panel made out of two (2) sections and one (1) lower

panel for each side of bank (field installed), four (4) panels

for each module in the bank (factory installed) and gasket

sealant tape for installation between modules . Install panels

by setting in place and locking down with the half turn

latches or self tapping screws .

Note: Panel package includes

a compressed 1” x 1” gasket sealant tape for installation

between modules

.

Install the tape on the outer frame on

the side of one module prior to installing the adjacent

modules.

CAUTION/ATTENTION

3 PHASE SCROLL

COMPRESSOR UNIT

UNITÉ COMPRESSEUR

SCROLL 3-PHASE

If this unit uses a 3 Phase Scroll

Compressor, the following instructions

MUST BE

followed:

• Unit power supply

MUST BE

wired

in the proper sequence to avoid

damage to the 3 Phase Scroll

Compressor;

• Scroll Compressors with

INCORRECT

rotation show the

following characteristics:

- High sound level;

- High suction pressure and low

discharge pressure;

- Low current draw.

• If any of the three above

characteristsics exist, swap

two of the three supply wires

at the disconnect and recheck

compressor for incorrect rotation.

Si cet appareil utilise compresseur

scroll 3-Phase, les instructions

suivantes doivent être suivies:

• L’alimentation de l’appareil doit

être monté dans l’ordre correct

pour éviter endommager le

compresseur scroll 3-Phase;

• Compressuers scroll avec

rotation incorrecte montrent les

caractéristiques suivantes:

- Haut niveau de son;

- Pression d-aspiration élevée

et une faible pression de

décharge;

- Faible ampérage.

• Si l’un des trois éléments

mentionnés ci-dessus sont

remplies, échanger deux des trois

lignes électriques alimen tant la

interrupteur de sécurité et vérifier

la rotation du compresseur.

Содержание CLIMACOOL UCR 30

Страница 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Страница 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Страница 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

Страница 41: ...39 www climacoolcorp com Condenser Layout for RC1 007A H24 and RC1 008A H24 1 Row 2 Fan 1140RPM...

Страница 42: ...40 www climacoolcorp com Condenser Layout for RC2 019A 026A and 31A H48 and RC2 038A H44 2 Row 4 Fan 1140RPM...

Страница 43: ...41 www climacoolcorp com Condenser Layout for RC2 018A X48 RC2 026A X40 and RC2 032A X44 2 Row 4 Fan 830 RPM...

Страница 47: ...45 www climacoolcorp com 45 www climacoolcorp com Condenser Layout for RC2 048A Q82 2 Row 8 Fan 540RPM...

Страница 78: ...76 www climacoolcorp com Wiring Diagram...

Страница 79: ...77 www climacoolcorp com Wiring Diagram...

Страница 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Страница 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...