35

www.climacoolcorp.com

Head Pressure Control Valve Operation (LAC-10)

since as the compressor unloads, the condenser’s capacity increases and additional flooding is required. Using the same

roof mounted remote condenser as in the earlier example (40°F evaporator and minus 20°F minimum ambient), a multiplier

of .79 is shown in Table 8. And since there is hot gas bypass (50%), this .79 is used to enter Table 10 to find a multiplier of .91.

This final multiplier is applied to the 119 pounds calculated earlier to arrive at the final extra charge requirement: 119 x .91 =

108 pounds . This is added to the normal system charge to arrive at a total system charge .

Table 8

Refrigerant

Minimum

Ambient

°F

Equivalent Length Of Tubing for

Each Return Bend

Density Factor - Pounds Per Foot Of Tubing

Tubing O.D. and Wall Thickness (Inches)

3/8”

(0.016)

1/2”

(0.017)

5/8”

(0.018)

0.875

(0.045)

1.125

(0.05)

1.375

(0.055)

3/8”

1/2”

5/8”

R-410A

-40

0.2

0.25

0.3

0.05

0.10

0.16

0.28

0.47

0.72

-20

0.05

0.10

0.15

0.27

0.46

0.70

0

0.05

0.09

0.15

0.26

0.45

0.68

20

0.05

0.09

0.14

0.25

0.43

0.66

40

0.05

0.09

0.14

0.24

0.41

0.63

60

0.04

0.08

0.13

0.23

0.39

0.60

70

0.04

0.08

0.13

0.23

0.39

0.59

Table 9

Condenser

Ambient

Temperature

°F

Percent of Condenser to be Flooded

High Suction Temperature A/C Chillers

Evaporating Temperature °F

35

40

45

50

80

0

0

0

0

70

0

0

0

0

60

26

20

10

4

50

45

40

33

28

40

56

42

46

42

30

64

60

55

51

20

69

66

62

59

0

76

73

70

68

-20

80

79

76

73

Refrigerant Charging Procedures for Head

Pressure Control Valve

Once the amount of extra refrigerant charge is calculated,

care must be taken in charging the system to ensure

the proper total amount of refrigerant getting into the

system . This is especially true if the ambient temperature

is below 70°F and the liquid drain valve (LAC) is throttling

the refrigerant flow from the condenser. A step by step

procedure is given below for the two possible situations

that can exist . And depending on the ambient temperature

at the time the system is charged, each should be carefully

followed to ensure proper system operation in both

summer and winter . In either case, a liquid seal must be

established in the receiver before the system can start to

function correctly .

Note:

While charging any system with head pressure control,

the outdoor ambient temperature must be known . And if the

system has hot gas bypass valves, it is important to know if

they are functioning during the charging procedure . To keep

this procedure as simple as possible, it is recommended that

the hot gas bypass valves be locked out (compressor fully

loaded) during charging .

Table 10

Condensing

Flooding with NO

Unloading

Percent of Full

Compressor

Capacity = 50%

05

0.50

10

0.53

15

0.57

20

0.60

25

0.63

30

0.66

35

0.69

40

0.72

45

0.74

50

0.76

55

0.79

60

0.81

65

0.83

70

0.86

75

0.88

79

0.91

80

0.92

85

0.96

Содержание CLIMACOOL UCR 30

Страница 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Страница 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Страница 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

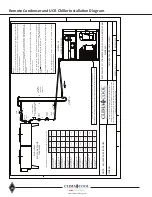

Страница 41: ...39 www climacoolcorp com Condenser Layout for RC1 007A H24 and RC1 008A H24 1 Row 2 Fan 1140RPM...

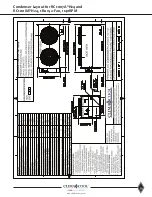

Страница 42: ...40 www climacoolcorp com Condenser Layout for RC2 019A 026A and 31A H48 and RC2 038A H44 2 Row 4 Fan 1140RPM...

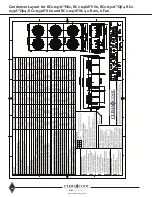

Страница 43: ...41 www climacoolcorp com Condenser Layout for RC2 018A X48 RC2 026A X40 and RC2 032A X44 2 Row 4 Fan 830 RPM...

Страница 47: ...45 www climacoolcorp com 45 www climacoolcorp com Condenser Layout for RC2 048A Q82 2 Row 8 Fan 540RPM...

Страница 78: ...76 www climacoolcorp com Wiring Diagram...

Страница 79: ...77 www climacoolcorp com Wiring Diagram...

Страница 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Страница 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...