36

www.climacoolcorp.com

Head Pressure Control Valve Operation (LAC-10)

Charging of Systems with Sporlan Head Pressure

Control in Ambient ABOVE 70°F

(After normal evacuation procedures)

Before starting system:

1 .

Connect refrigerant cylinder to a charging or gauge

port on the receiver outlet valve .

2 .

Open the receiver valve approximately one-half way

(so receiver and liquid line are connected to charging

or gauge port) .

3 .

Charge liquid refrigerant into the high side of the system .

Weighing the charge is recommended with

the initial charge consisting of approximately 2 .5 pounds

per system ton .

4 .

Remove the refrigerant drum and connect it to the

suction side of the compressor .

5 .

Charge refrigerant vapor into the low side until the

pressure is above atmospheric pressure . Do not admit

liquid refrigerant into the low side .

6 .

Start the system .

7 .

Observe sight glass (at receiver outlet) to see if system

is properly charged for normal refrigeration cycle .

CAUTION: Bubbles in the sight glass can be caused by

flashing due to pressure drop from pipe or accessory

losses, etc.

8 .

If the sight glass shows bubbles, more refrigerant

should be added, while allowing sufficient time for the

refrigerant to stabilize and clear the sight glass .

9 .

The extra refrigerant charge for head pressure control

should be weighed in now by admitting liquid refrigerant

to the high side .

Charging of Systems with Sporlan Head Pressure

Control in Ambient BELOW 70°F

(After normal evacuation procedures)

Note:

When charging in ambient below 70°F the procedure

is very critical . Be sure to adhere to the following steps

without fail . Failure to do so will result in overcharging

the system .

1 .

Follow instructions 1 through 9 above .

2 .

If the LAC valve setting is correct for the system being

charged, it is quite likely that some refrigerant will be

backed up into the condenser and the sight glass will

indicate bubbles in the liquid line .

3 .

Add more refrigerant, while allowing sufficient time for

the refrigerant to stabilize and clear the sight glass .

4 .

At this point the system is correctly charged for this type

of head pressure control at the ambient temperature

that exists while the charging procedure is taking place .

5 .

If the system is designed to operate at ambient below

the ambient that exists during charging, additional

charge will have to be added now .

6 .

To calculate the additional charge required, follow the

examples outlined under the Refrigerant Charge section .

Remember that the “head pressure control charge” is

partially charged already . Refer to Tables 9 and 10 .

The difference in percentages between the minimum

design

ambient temperature and the ambient temperature at the

time the system is charged gives the percent of

extra

charge

still needed in the system . Example: if this system was

charged at an ambient of 50°F, there is approximately 40%

of the

extra

charge in the system . This holds true as long as

the compressor is not allowed to unload during charging .

Therefore, the additional charge required is 95 minus 40 or

55% of the total

extra

charge calculated previously . This is

.55 x 119 or 65 pounds .

Service Procedures

There are several possible causes for system malfunction

with “refrigerant side” head pressure control and these

may be difficult to isolate from each other. As with any

form of system trouble-shooting, it is necessary to know

the existing operating temperatures and pressures

before system problems can be determined . Once the

actual malfunction is established, it is easier to pinpoint

the cause and then take suitable corrective action . The

following chart lists the most common malfunctions, the

possible causes, and the remedies . Since the LAC valves are

hermetic, the valves cannot be disassembled for inspection

and/or replacement of parts . The valves must be replaced

if they become inoperative .

Содержание CLIMACOOL UCR 30

Страница 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Страница 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Страница 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

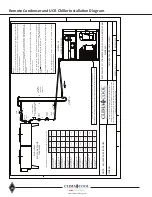

Страница 41: ...39 www climacoolcorp com Condenser Layout for RC1 007A H24 and RC1 008A H24 1 Row 2 Fan 1140RPM...

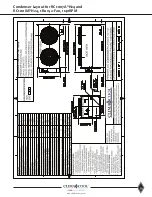

Страница 42: ...40 www climacoolcorp com Condenser Layout for RC2 019A 026A and 31A H48 and RC2 038A H44 2 Row 4 Fan 1140RPM...

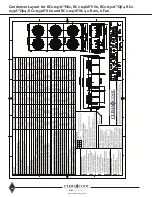

Страница 43: ...41 www climacoolcorp com Condenser Layout for RC2 018A X48 RC2 026A X40 and RC2 032A X44 2 Row 4 Fan 830 RPM...

Страница 47: ...45 www climacoolcorp com 45 www climacoolcorp com Condenser Layout for RC2 048A Q82 2 Row 8 Fan 540RPM...

Страница 78: ...76 www climacoolcorp com Wiring Diagram...

Страница 79: ...77 www climacoolcorp com Wiring Diagram...

Страница 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Страница 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...