3-4

F-459-R1

HYDRAULIC OIL, MOTORS, PUMPS AND CYLINDERS

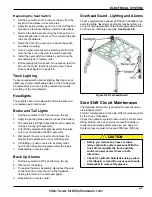

Hydraulic Pump Service

NOTE

The hydraulic lift pump used on the SLT30/35 AC has no

serviceable parts and is repaired by replacement only.

When replacing the lift pump, make sure that the

hydraulic oil is clean and that the hydraulic system has a

new clean filter. See “Changing Hydraulic Oil” and

“Changing Hydraulic Filter” on page 3-2.

Replacing the Hydraulic Pump and

Motor

NOTE

The AC motor and pump are located in the center of the

truck on the right side of the driver’s feet.

1.

Remove the key and place in a secure area.

2.

Perform the Lock Out/Tag Out procedure.

3.

Disconnect the battery.

4.

Remove the floor plate and the main side cover to

expose the hydraulic pump and motor.

5.

Using the exposed female threads on the motor,

attach the hoist using a threaded bolt and washers.

6. To relieve any static pressure, SLOWLY loosen and

disconnect the pressure and suction hoses from the

hydraulic pump. Place shop rags under the

connections to catch hydraulic oil.

7.

Mark and disconnect the Deutsch electrical

connectors.

8.

Mark and disconnect the 3 heavy gauge electrical

cables.

9.

Remove four M8-1.25 X 20 motor fasteners, to allow

the pump and motor assembly to be moved out of the

frame.

10. Using an overhead hoist, remove the pump and

motor assembly from the truck and place it the repair

area. NOTE: Assembly is very heavy.

11. Assemble in reverse procedure.

Figure 3-4: Hydraulic Motor and Pump Assembly

Hydraulic Control Valve

Assembly

General

While a leaky control valve may be fixed by installing a

service kit, if there are more serious problems to the

hydraulic spool, Landoll recommends a complete

hydraulic valve replacement.

The following procedure explains how to replace a

specific valve should a sluggish or sticking valve spool be

suspect.

If you remove the valve from the truck for servicing

(hex head screws and hardware), when reinstalling

the valve be certain to tighten the mounting screws

in a staggering fashion while applying equal

pressure to all screws. If the screws are not

tightened and torqued evenly, you could create a

stress crack, thus internal oil leaks, rendering the

valve defective.

NOTE

• The main hydraulic pump for lift, tilt, pivot, and shift

(mast functions) is a fixed displacement gear pump

(2.008 cu. inch/rev). System pressure must not

exceed 3,000 psi, ±65 psi (206 bar, ±4 bar)

maximum.

• The main pump pressure relief valve is part of the

hydraulic control valve.

https://www.forkliftpdfmanuals.com/

Содержание Drexel SLT30 AC

Страница 2: ...https www forkliftpdfmanuals com...

Страница 36: ...2 16 F 459 R1 TIRES BRAKES AND DRIVETRAIN Table provided for general use NOTES https www forkliftpdfmanuals com...

Страница 69: ...DREXEL SLT30 35 AC CALIBRATION PROGRAMMING 5 17 https www forkliftpdfmanuals com...

Страница 70: ...5 18 F 459 R1 DREXEL SLT30 35 AC CALIBRATION PROGRAMMING https www forkliftpdfmanuals com...