2-12

F-459-R1

TIRES, BRAKES AND DRIVETRAIN

Bleeding Brakes

NOTE

Bleeding the brake system is necessary to remove any

air that is trapped when replacing brake lines, brake

calipers or the master cylinder. To avoid extensive

damage to the system, use only DOT 3 brake fluid.

WARNING

NOTE

Check the fluid level often during the bleeding operation

and add fluid as needed to prevent the level from falling

low enough to allow air bubbles into the master cylinder.

Use only new DOT 3 brake fluid from a sealed container.

NEVER use old or used brake fluid. It contains moisture

which will deteriorate the brake system components.

IMPORTANT

It is necessary to bleed both wheels if air has entered

the system. Air in the brake system can be caused by

low fluid level, a leaking brake line or a brake line that

has been disconnected. If the brake pedal feels

spongy when pressed and travels almost to the

mechanical stop but regains height when pumped,

air has entered the system. The system must be bled.

If no fittings were recently opened for service, check

for leaks that would have allowed air into the system

and repair leaks before attempting to bleed the

system.

DO NOT allow fluid to go inside of the brake drum

and onto the brake pad. It will contaminate the brake

shoes and cause failure.

NOTE

Have an assistant available, as well as a supply of brake

fluid, an empty container, a length of 3/16” (4.763 mm)

clear plastic or vinyl tubing to fit over the cylinder bleeder

fitting and a six point wrench to open and close the fitting.

1.

Set the key switch to OFF, remove the key from the

key switch and put in a secure place.

2.

Apply the parking brake, perform a Lock Out/Tag Out

procedure and disconnect the battery.

3.

Block the wheels so that the truck can’t move.

4.

Start with the right wheel (the wheel farthest from the

master cylinder).

IMPORTANT

Be careful when handling bleeder screws. Rust may

cause the fitting to break. Spray the fitting with

penetrating oil before attempting to loosen. Use a

6-sided wrench or socket instead of a 12-sided.

5.

Loosen the bleeder fitting slightly, then tighten it

where it is snug but can be loosened quickly and

easily.

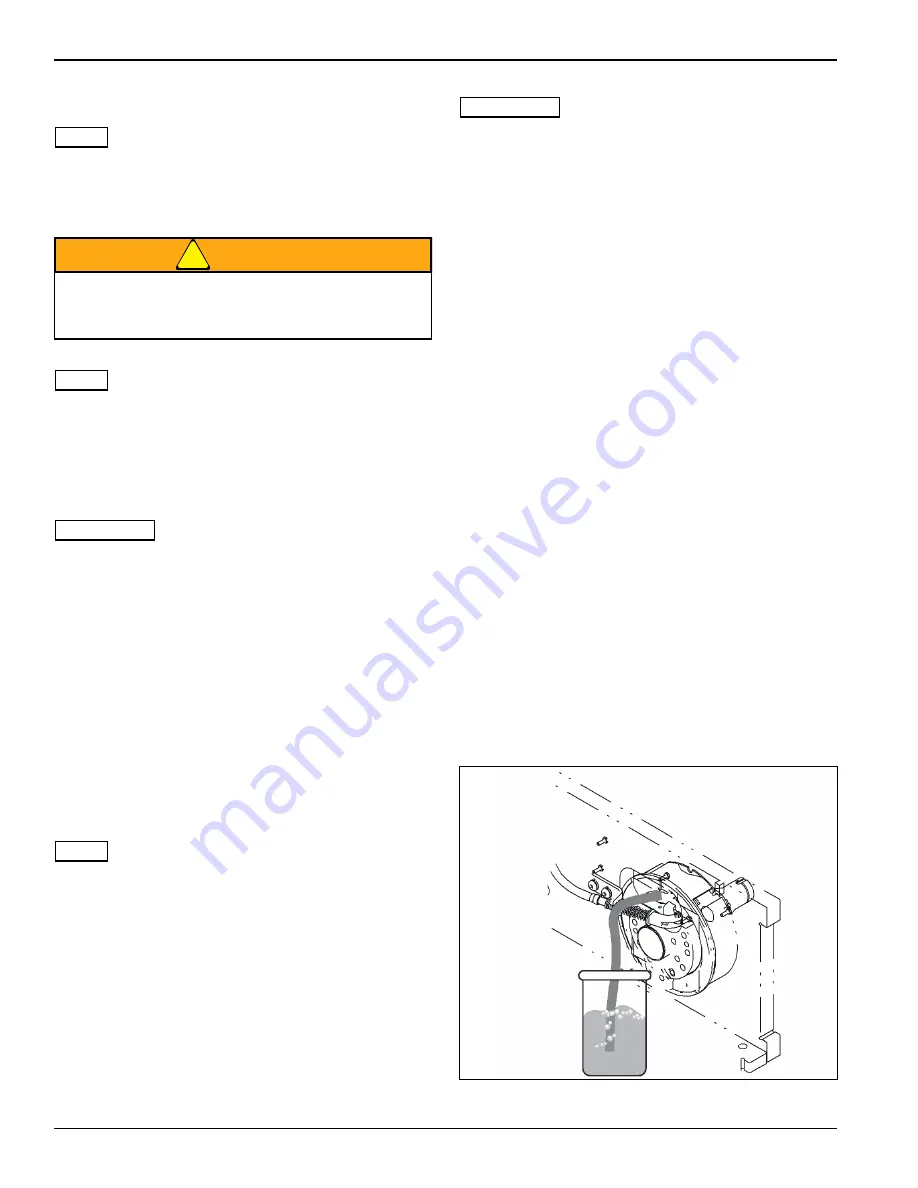

6.

Fit a length of tubing over the bleed screw and

immerse the other end in the container of new brake

fluid. Check that the tubing fits tightly over the

bleeder fitting.See Figure 2-10.

7.

Check fluid level in the master cylinder. Fill before

you begin.

8.

Have someone slowly press on the brake pedal

several times to build pressure in the system, then

hold the pedal down.

9.

Loosen the cylinder bleed screw until fluid starts to

flow. Watch for air bubbles at the immersed end of

the tube.

10. When the brake pedal bottoms, tighten the bleed

screw, then release the pedal. DO NOT release

pressure on the pedal until the bleed screw is

tightened.

11. Repeat Steps 8 through 11 as many times as needed

until the fluid draining in the container is free of air

bubbles.

12. Fill the master cylinder fluid level and add as needed

before bleeding the other side.

13. Check the operation of the brakes. The pedal should

feel solid when depressed, with no softness.

If necessary, repeat this procedure.

Figure 2-10 Bleeding Brakes

Wear eye protection. If brake fluid comes in

contact with your eyes, immediately rinse them

with water and seek medical attention.

https://www.forkliftpdfmanuals.com/

Содержание Drexel SLT30 AC

Страница 2: ...https www forkliftpdfmanuals com...

Страница 36: ...2 16 F 459 R1 TIRES BRAKES AND DRIVETRAIN Table provided for general use NOTES https www forkliftpdfmanuals com...

Страница 69: ...DREXEL SLT30 35 AC CALIBRATION PROGRAMMING 5 17 https www forkliftpdfmanuals com...

Страница 70: ...5 18 F 459 R1 DREXEL SLT30 35 AC CALIBRATION PROGRAMMING https www forkliftpdfmanuals com...