117

3.6 Adjusting the Peel-Detection Rollers

REGIUS MODEL 190 Service Manual Ver.1.00 2004.11.01

3.6

Adjusting the Peel-Detection Rollers

3.6.1

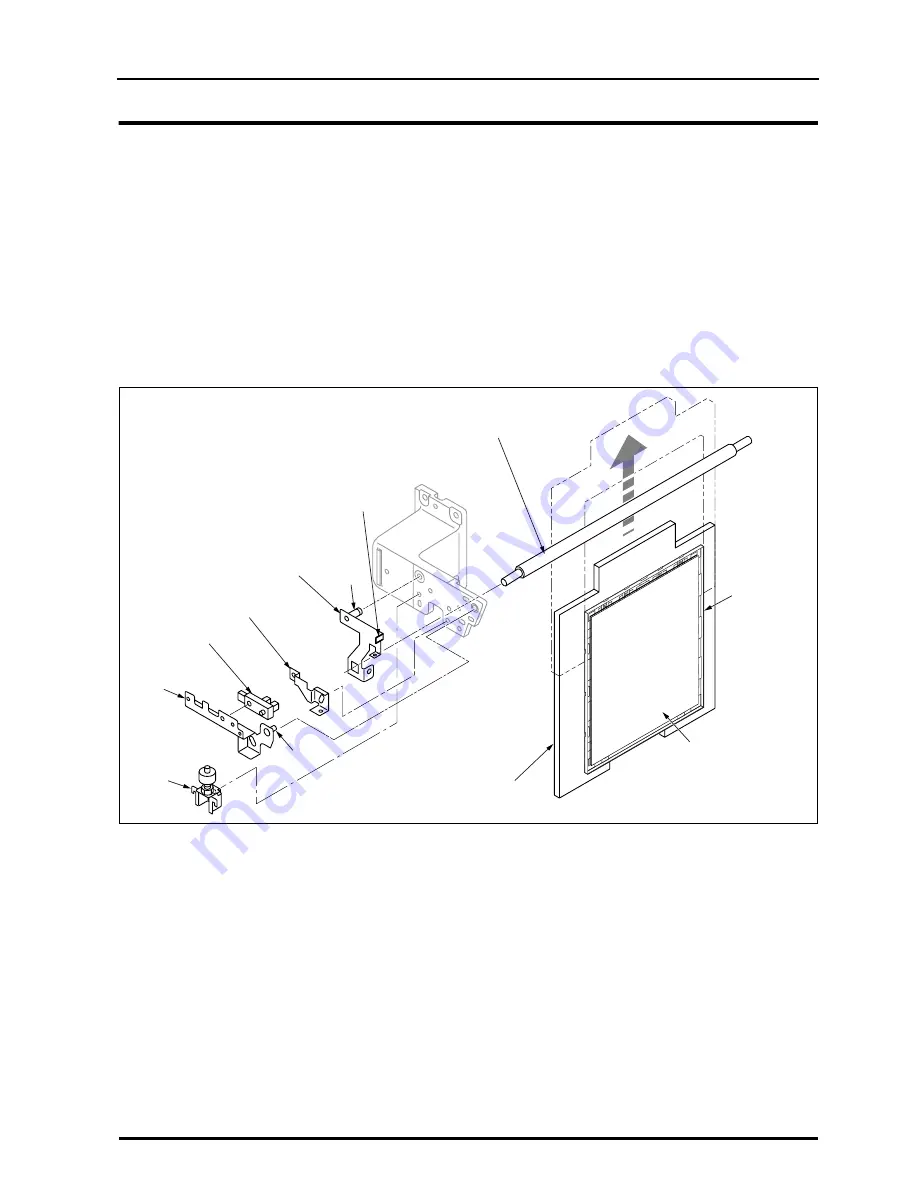

Peel detection mechanism

The REGIUS 190 has been designed such that, when subscanning operation is being carried out, there is a gap

of approximately 1 mm between the optical beam condensing section and the plate surface. However, in situa-

tions such as where abnormal adherence of double-sided adhesive tape leads to peeling of the plate from the

back plate, any attempted subscanning operation could result in interference of the plate with the optical unit. In

order to avoid such interference, a peel detection roller is provided in the position where the elevating plate is just

enters the operational area of optical unit.

•

Main Components of Peel Detection Mechanism

Sensor Actuator

Shaft "A"

Shaft "B"

1

4

6

3

5

2

Magnetizing Plate

REGIUS Plate

Back Plate

Содержание REGIUS 190

Страница 7: ...VI REGIUS MODEL 190 Service Manual Ver 1 00 2004 11 01...

Страница 13: ...Blank...

Страница 27: ...xx REGIUS MODEL 190 Service Manual Ver 1 00 2004 11 01...

Страница 28: ...Chap 1 Overview...

Страница 29: ...Blank Page...

Страница 43: ...16 1 3 Layout of Controlling Components REGIUS MODEL 190 Service Manual Ver 1 00 2004 11 01...

Страница 45: ...Blank Page...

Страница 52: ...Chap 2 Disassembly and Reassembly...

Страница 53: ...Blank Page...

Страница 118: ...Chap 3 Maintenance Adjustment...

Страница 119: ......

Страница 153: ...126 3 9 Adjusting the Position of Insertion Guide Switch SW4 REGIUS MODEL 190 Service Manual Ver 1 00 2004 11 01...

Страница 154: ...Chap 4 Troubleshooting...

Страница 155: ......

Страница 194: ...A Appendix...

Страница 195: ......

Страница 218: ...191 A 5 Parts Layout Diagram REGIUS MODEL 190 Service Manual Ver 1 00 2004 11 A 5 2 SCB2 System Control Board...

Страница 219: ...192 A 5 Parts Layout Diagram REGIUS MODEL 190 Service Manual Ver 1 00 2004 11 A 5 3 ADB2 A D Board...

Страница 220: ...0676 55030 B 0412TE...