92

Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02

Service and maintenance

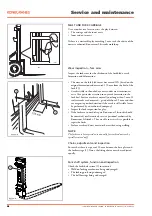

MAST AND FORK CARRIAGE

Use a crowbar or a lever to assess the play between:

• The carriage and the inner mast.

• Inner and outer mast.

If there is a noticeable play exceeding 5 mm, seek the advice of the

nearest authorised Konecranes Lifttrucks workshop.

Wear inspection – fork arms

Inspect the fork arms for the thickness of the fork blade. crack

formation and deformation.

• The wear on the fork blade must not exceed 10% (based on the

original dimension and measured 150 mm from the heal of the

fork (1)).

• Cracks visible to the naked eye must under no circumstances

exist. Give particular attention to any crack formation in the

fork heal. Surface cracks are normally not longer than 5 mm. If

surface cracks are discovered – grind off about 0.5 mm and then

use magnetic powder detection if the crack is still visible (must

be performed by an authorised company).

• Inspect the fork suspension for play.

• If the forks are in need of repair, Konecranes Lifttrucks should

be contacted, or alternatively, service personnel authorised by

Konecranes Lifttrucks. They are able to assess if it is possible to

repair the forks.

• Surface cracks and wear must not be rectified using welding.

NOTE

The forks must be inspected once annually for crack indications by

specially trained staff.

Chains, adjustments and inspection

Ensure that there is a space of 10 mm between the base plate and

the fork carriage (2). If not, the lifting chains must be readjusted

equally.

Fork shaft system, function and inspection

Check the fork shaft system (1) in terms of:

• Weld on locking mechanism being undamaged.

• The locking pin being undamaged.

• The ball bearings being undamaged.