Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02

53

Service and maintenance

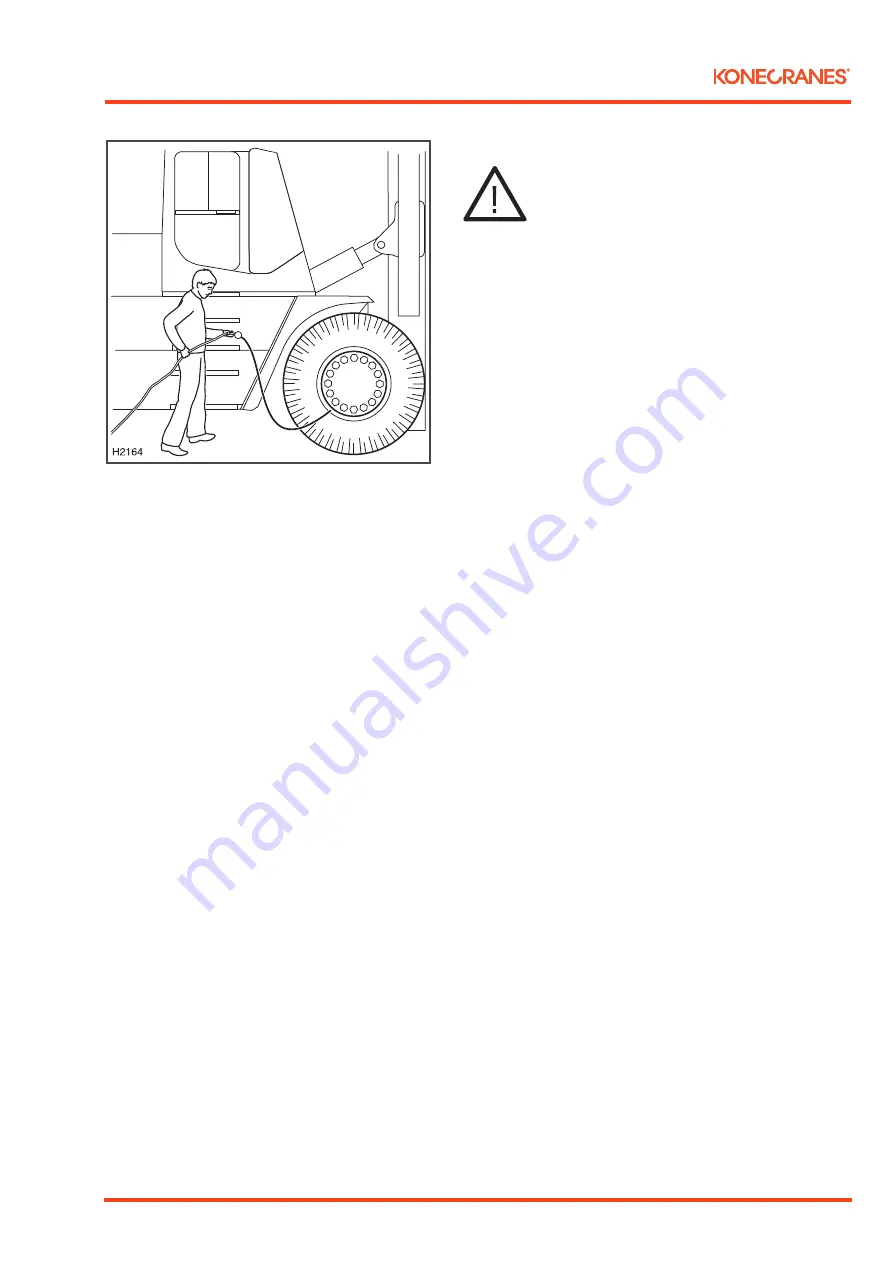

Inflating of tyres

DANGER

High pressure tyres. Always stand on the side of

the wheels when you release the air from or fill

the tyres.

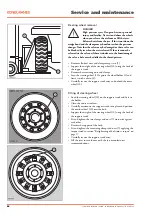

• Never hit a tyre or wheel that is partially or fully filled.

• The tyre must not be inflated until all parts have been fitted.

• The wheel components must never be fitted by being hit with

a hammer when the tyre is being inflated.

• If the tyre has been deflated, remove the wheel and examine it

for any damage.

• It is important to always use approved components for the

wheels.

• Ensure that all the parts are in place when the fitting pressure

has been reached.

• Final inflating to the maximum pressure must be done on

machine or in a safety cage with the correct dimensions for the

tyre in question.

• If a safety cage is being used, the tyre can be filled to full

pressure.

If not, the tyre must be filled to the fitting pressure stated by

the tyre manufacture.

• Do not exceed the tyre pressure that has been prescribed. If the

type of tyre or wheel is changed, another tyre pressure may be

applicable, please contact Konecranes Lifttrucks.

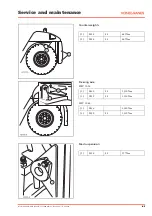

Fill in accordance with the following.

• When filling the tyre, an air filter and water separator should be

installed on the line from the compressor in order to avoid

corrosion on the wheel.

• Ensure that the locking ring and locking lug are in the correct

position before filling is commenced.

• Connect the compressor to the nipple on the tyre.

• Stand on the side of the tyre until the fitting pressure has been

reached.

• Ensure that all the parts are in place when the fitting pressure

has been reached.

• Fit the tyre in accordance with instructions.

• Fill the tyre to the prescribed pressure in accordance with the

tyre manufacturer's specifications.