50

Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02

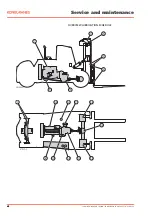

Service and maintenance

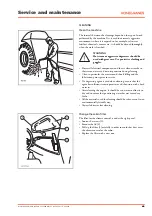

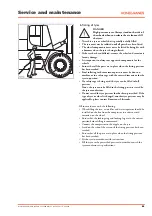

PRESSURE DRAINING OF THE HYDRAULIC SYSTEM

WARNING

High pressure accumulators in the hydraulic

system maintains the braking function in the

event of an engine breakdown.

Danger of serious personal injury

Always drain the brake pressure before performing

maintenance or service work on the machine.

Never loosen a hydraulic hose or connection without first

ensuring that the brake pressure has been drained.

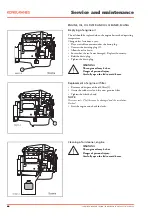

• Loosen the locking nut using a 11/16" ring spanner (1).

• Loosen the draining nut using a 3/16" Allen key (2).

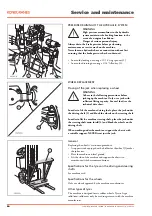

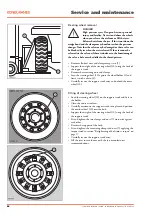

WHEEL REPLACEMENT

Placing of the jack when replacing a wheel

WARNING

Adhere to the following precautions before

jacking up the machine. Only use a jack with

sufficient lifting capacity. For axel load, see the

technical data sheet.

In order to lift the machine driving shaft, place the jack under

the driving shaft (1) and block the wheels on the steering shaft.

In order to lift the machine steering shaft, place the jack under

the steering shaft main shield (2) and block the wheels on the

driving shaft.

When working under the machine, support the chassis with

a suitable support. NEVER trust just the jack.

General

Replacing the wheel is a two-man procedure.

• A support truck equipped with a holder for the wheel (1) makes

the job easier.

• Place the machine on level ground.

• Lift the side of the machine and support the chassis in

accordance with the recommendations.

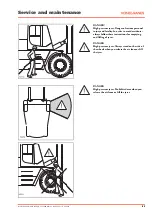

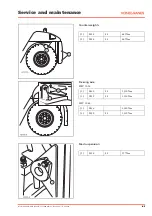

Specifications for the tyres on the driving and steering

shafts

See machine card.

Specifications for the wheels

Only use wheels approved by the machine manufacturer.

Other types of tyres

The machine is designed for air rubber wheels. Tyres of type

solid/semi-solid must only be used in agreement with the machine

manufacturer.