Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02

7

Presentation of the machine

PRESENTATION OF THE MACHINE

TECHNICAL DESCRIPTION

The designation SMV 33-1200 B means:

SMV =

Product name

33 =

33 ton lifting capacity,

1,200 =

1,200 mm load centre

B =

series designation

The engine is a water cooled, turbo charged 6 cylinder diesel

engine. The engine drives a transmission through a torque

converter. DANA has a transmission version with four

forward gears and four backward gears. ZF has a transmission

version with four forward gears and three backward gears.

Both DANA and ZF have a transmission version with three

forward gears and three backward gears.

All machines are provided with a gear lever for four forward

but only three gears can be activate on certain models. The

gear change is done electrically with gears for driving

forward/backward. The torque converter is equipped with

an oil cooler under the engine cooler. The transmission has

a disconnect valve that is manoeuvred via the brake pedal

in the cabin.

The disconnection valve disconnects the transmission so that

the operator can control the braking and at the same time

retain a high engine revolution during stacking.

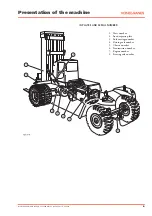

The front axle is driven by the transmission via the prop

shaft. This axle is of a double-reduction heavy duty type with

a conic pinion as its primary gear, hub planetary gear as its

secondary gear, load reduced axle pegs and conical roller

bearings.

The steering shaft is mounted in "spherical" bushings that

allow sufficient wheel movements for stability on uneven

surfaces. The parallel tie rods are between the steering

cylinders and the wheel axles.

The brake system consists of a oil cooled wet disc brake

system. The foot brakes are operated using the foot brake

valve and affects the drive axle.

The parking brake operates electrically and affects a hydraulic

cylinder on the prop shaft. The parking brake is always active

as long as it has not been released using electrical energy.

The axial piston pumps together with a gear pump are fitted

directly on the transmission. The gear pump builds up the

accumulator pressure for the foot and parking brakes. The

variable piston pump provides the steering system and the

different lift functions with pressure. The system is load

sensing.

The steering is completely servo assisted. In the event of an

engine breakdown, it is still possible to steer the machine for

a limited period of time without power assistance but it will

be heavy.

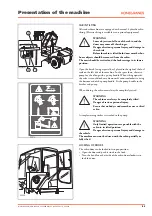

WARNING

In the event of engine breakdown, the

machine must be stopped in a safe manner.

Machine sizes 10-16 are equipped with a directional control

valve and machine sizes 18-60 are equipped with two. These

directional control valves are fitted to the chassis and

operated from the cabin using power assisted levers to the

right of the driver. These control the functions for mast lifts,

tilts, sideshift movement of the fork carriage and the fork

spreading and any extra functions.

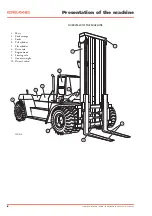

The mast consists of an outer and an inner mast, a fork

carriage, two lift cylinders and two tilt cylinders. The inner

stand section moves along the outer using mast wheels and

support rollers. The mast is mounted on two axles in the

chassis using bearings. The fork carriage is of a rolling type

with sideshift movement and fork spreading.

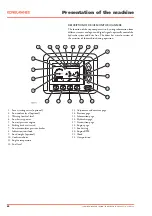

The driver's cabin fulfils international safety standards and is

suspended on the chassis on rubber mounts to protect the

driver from vibrations. Getting into the cabin is done from the

left using the steps in the machine. When the driver seat is

turned 90°, it is also possible to leave the cabin to the right.

All hydraulic controls for the lifting functions are situated on

the console to the right of the driver seat.

The parking brake, switches for electric optional equipment's,

instruments, gauges and warning indicators are on the front

instrument panel.

Gear change controls, levers for driving direction indicators

and the windscreen wipers are on the steering column.

The electrical system is 24 volt using two heavy duty batteries

connected in line.

Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02