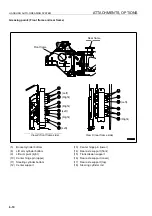

ATTACHMENTS, OPTIONS

HANDLING AUTO-GREASING SYSTEM

6-5

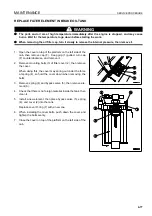

1) One person removes plug (4) from one injector, then

stays there.

This plug (4) is installed to the manifold end of each end

injector.

If air must be bled from the main piping, remove this plug.

2) The other person presses the auto-greasing switch to

start the grease pump.

3) Discharge the grease containing air (milky white in many

cases) from the injector. If normal grease comes out, stop

the grease pump.

4) Tighten plug (4) of the injector to prevent the grease from leaking.

It is impossible to see if the air has been bled by simply checking the pressure gauge. Even if air is mixed in the

grease, the auto-grease system operates since the discharge pressure of the grease pump is high. To see if the

greasing system is working normally, check that the grease pump is balanced and stopped in the specified

(operating) time (60 seconds).

4.

Method of bleeding air from pressure switch This work

shall be performed by two persons.

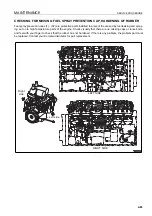

1) Open transmission inspection cover (5) at the rear of the

cab. One person removes pressure switch (7) from block (6),

then stays there.

2) The other person presses the auto-greasing switch to

start the grease pump.

3) Discharge the grease containing air (milky white in many

cases) from the block (6). If normal grease comes out, stop

the grease pump.

4) Install pressure switch (7) to block (6). (Check that grease is not leaking.)

5.

Method of bleeding air from supply line

This work shall be performed by two persons.

1) One person removes supply line pressure gauge (8) from

block (6), then stays there.

2) The other person presses the auto-greasing switch to

start the grease pump.

3) Discharge the grease containing air (milky white in many

cases) from the block (6). If normal grease comes out, stop

the grease pump.

4) Install pressure gauge (8) to block (6). (Check that grease

is not leaking.)

NOTICE

If air is left in the circuit, the grease pressure will not rise

to the specified level or will take a long time to rise to the

specified level, and the injector will not work normally.

View Z

From grease pump

Содержание WA800-3E0

Страница 2: ......

Страница 3: ...FOREWORD 11...

Страница 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Страница 66: ...GENERAL VIEW OPERATION 3 4...

Страница 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Страница 224: ...TROUBLESHOOTING OPERATION 3 162...

Страница 225: ...MAINTENANCE 14 WARNING Please read and make sure that you understand the SAFETY section before reading this section...

Страница 309: ...SPECIFICATIONS 15...

Страница 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Страница 331: ...INDEX 17...

Страница 332: ...INDEX 7 2...

Страница 335: ...COLOPHON 18...