Operation Manual 7310 EPSHP

14

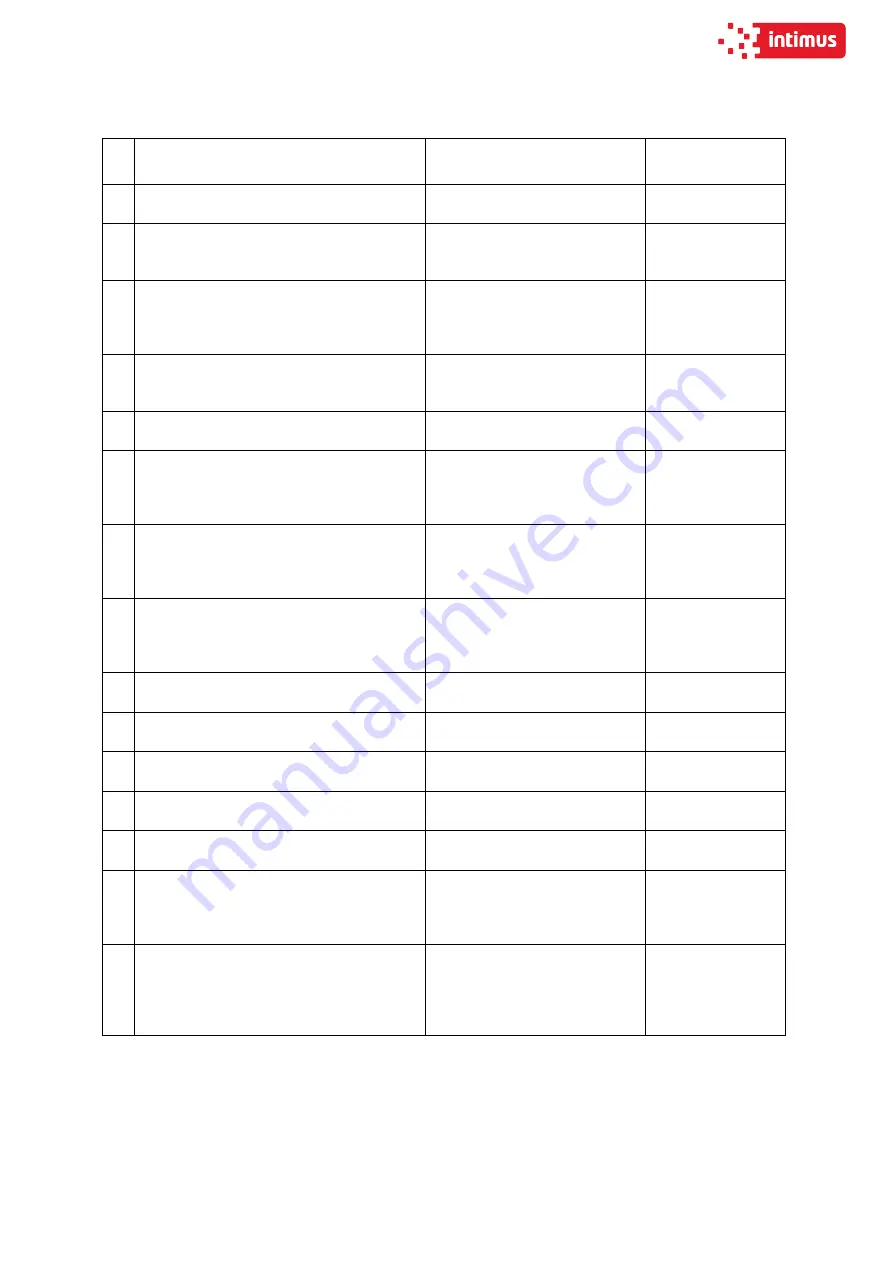

Table 3: Safety measures used to eliminate hazards (according to Figure 3)

Factors and / or dangerous places Security measures

Identification

I MECHANICAL

1. The lever assembly mechanism of the

pressure beam drive

Fixed cover

Machine body

Emergency stop

1, 3, 4, 10, 11

2

9

2. Hydraulic system

Machine body

Fixed cover

Front table

Emergency stop

2

3, 4, 10, 11

8

9

3. The belt drive for the drive mechanism of

the backguage beam

Machine body

Front table

Emergency stop

2

8

9

4. The screw mechanism of the backguage

drive

Cutter body

Fixed cover

2

6, 12

5. Motor, lever mechanism of the knife drive

mechanism

Fixed cover

Machine body

Front table

Emergency stop

1, 3, 4, 10, 11

1, 2

8

9

6. Approach move of the knife beam

Fixed cover

Safety curtain

Two-handed device

Emergency stop

1

7

5

9

7. Approach move of clamp beam

Fixed cover

Safety curtain

Two-handed device

Emergency stop

1

7

5

9

8. Approach move of backguage

Fixed cover

Emergency stop

1, 6

9

9. Manipulation with a knife during its

replacement

Transport handles

Special protective packaging

10. Sharp edges and corners of the cutter

elements

Refraction, dullness, rounding

11. Uneven or rough surfaces

Precise workpiece machining

Paint coatings

II ELECTRICAL

1. Direct contact of active elements

Closed housing

Partially reduced voltage supply

to the control system up to 24V

AC/DC

2, 13

2. Indirect touch

Protection against indirect

contact according to PN-EN

60204-1.

Continuity of the protective

conductor

Содержание INT-GU-07310EPSHP

Страница 5: ...Operation Manual 7310 EPSHP 5 EC Conformity Declaration...

Страница 42: ...Operation Manual 7310 EPSHP 42 Figure 26 Figure 27...

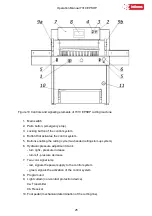

Страница 55: ...Operation Manual 7310 EPSHP 55 Figure 43 Adjusting elements of backguage...

Страница 61: ...Operation Manual 7310 EPSHP 61 Figure 50 Lubrication point of the knife assembly lever...

Страница 66: ...Operation Manual 7310 EPSHP 66 PROGRAM MODULE OPERATOR MANUAL DOP B07S410 7...