Operation Manual 7310 EPSHP

63

DANGER!

Danger of burns due to hot oil!

Danger of hydraulic oil splash!

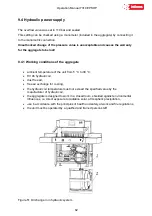

According to the recommendations of the hydraulic power supply manufacturer, the oil in it

should be replaced after a year of intensive work.

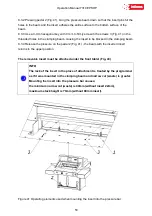

To change the oil, unscrew the drain plug 2 (fig. 51) located in the bottom of tank 1.

Old oil should be drained while it is still warm.

Fresh oil should be poured after first screwing in the drain plug 2 through the filler opening 1.

(Fig. 51)

DANGER!

Risk of injury!

After lubrication: Using a cloth, completely remove any excess lubricant (grease, oil), in

particular from the table surface on which the cutting material is laid and the work pieces in

contact with the cut material, i.e the knife body and the pressure beam.

9.5 Inspections

9.5.1 General recommendations

•

After each change, clean the machine (mainly from paper dust)

•

Pay attention to the cleanliness of contacts of control elements (contactors,

connectors)

•

Check the screw connections of the cutter elements and if necessary, tighten the

screws.

9.5.2 Checking hydraulic hoses

Check regularly that the hose is not damaged or frayed, and check the oil level.

Recommended test criteria for hydraulic hoses:

•

Damage to the inner layer (scratches, cuts, cracks)

Содержание INT-GU-07310EPSHP

Страница 5: ...Operation Manual 7310 EPSHP 5 EC Conformity Declaration...

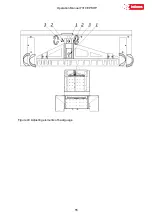

Страница 42: ...Operation Manual 7310 EPSHP 42 Figure 26 Figure 27...

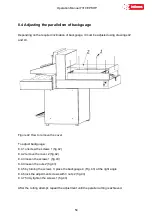

Страница 55: ...Operation Manual 7310 EPSHP 55 Figure 43 Adjusting elements of backguage...

Страница 61: ...Operation Manual 7310 EPSHP 61 Figure 50 Lubrication point of the knife assembly lever...

Страница 66: ...Operation Manual 7310 EPSHP 66 PROGRAM MODULE OPERATOR MANUAL DOP B07S410 7...