Operation Manual 7310 EPSHP

56

9. MAINTENANCE

DANGER!

Maintenance and lubrication work may only be carried out after turning off the

machine (main switch in position "0").

9.1 Daily maintenance

Every day, remove all waste from the cutter and the operator's working space.

9.2 Treatments that should be performed cyclically

At regular intervals, waste and dirt should be removed from hard to reach machine and

surrounding areas:

•

Regularly remove paper waste from the press and knife drive holes

•

Air intakes for motors must be kept free of dust and debris.

•

DANGER!

Caution – Fire hazard with insufficient ventilation!

The machine guards must be put back I nto place immediately after

maintenance work has been completed!

9.3 Lubrication

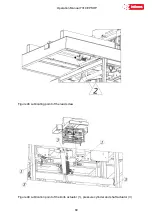

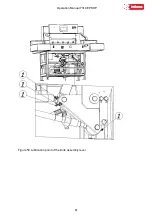

The list of lubrication points is shown in Figures 46, 47, 48, 49, 50 and described in table 12.

Access to lubrication points is possible after removing the covers shown in Figs. 44, 45, 48,

50.

When lubricating the knife assembly, use the controls as when changing the knife (Chapter

8.1)

Lubrication of the side surfaces of the guides as well as the surface of the knife body in

contact with the guides should be carried out in the upper (Fig. 46a) and lower position of the

knife body (Fig. 46b). Lubricate recommended places on both sides of the cutter.

In places requiring lubrication with a grease, apply grease with a grease gun. It is enough to

press the trigger of the lubricator 2-3 times.

The indicated places should be lubricated once a week!

Содержание INT-GU-07310EPSHP

Страница 5: ...Operation Manual 7310 EPSHP 5 EC Conformity Declaration...

Страница 42: ...Operation Manual 7310 EPSHP 42 Figure 26 Figure 27...

Страница 55: ...Operation Manual 7310 EPSHP 55 Figure 43 Adjusting elements of backguage...

Страница 61: ...Operation Manual 7310 EPSHP 61 Figure 50 Lubrication point of the knife assembly lever...

Страница 66: ...Operation Manual 7310 EPSHP 66 PROGRAM MODULE OPERATOR MANUAL DOP B07S410 7...