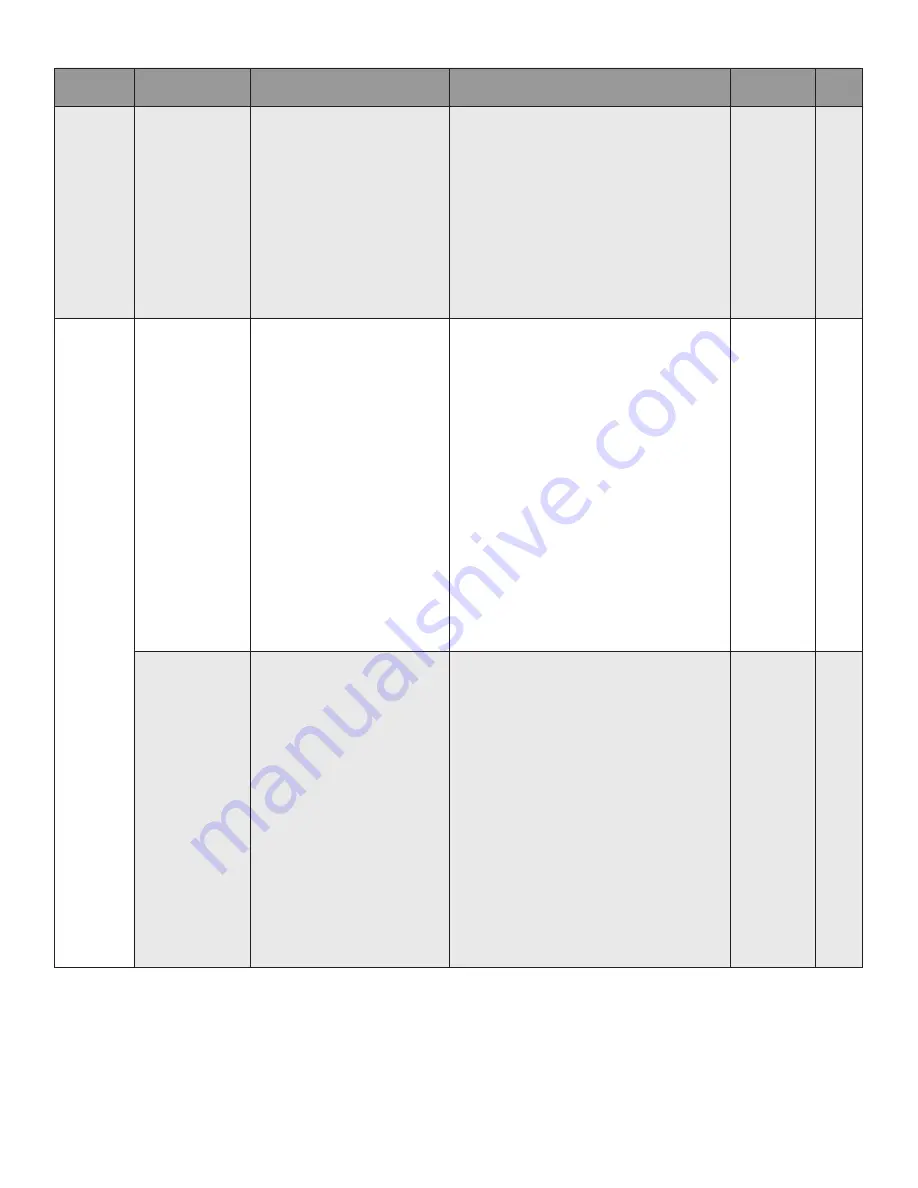

SV2 Series Safety Shut-off Valves

198

32-00029—02

Fault

Category

Fault

Description

Detailed Description

Remediation Steps

Comments Fault

#

Phase

Incoming

voltages out of

phase

Valve incoming L1 VAC to

POC or VPS or L1 VAC from

burner management system

to valve ILK IN, MV1 / MV2 is

out of phase.

1.) Reset valve and burner management

system, monitoring for proper operation.

2.) Check the valve power supply to make

sure that both frequency and voltage meet

the specifications.

3.) Verify that the valve, burner

management system and associated

devices are fed from the same phase. If a

VFD (variable frequency drive) is present,

ensure that it does not share a common

neutral or ground.

Warning

indication

for SV2

valve.

15

POC

POC (proof

of closure)

switch(es)

signal fault

Valve POC (proof of closure)

switch(es) signal is not valid.

Frequency or duty is out of

expected range.

Remove power and shut-off gas supply as

necessary.

1.) Remove valve front electrical enclosure

and inspect L1, Neutral, and POC wiring

connection for proper seating, pin

engagement and cleanliness. Correct any

errors.

2.) Check the valve power supply to make

sure that both frequency and voltage meet

the specifications.

3.) Replace cover and restore power and

gas. Reset valve and burner management

system, monitoring for proper POC

operation in conjunction with valve LEDs

and burner management system inputs.

4.) If fault persists, replace valve main

electronics.

10

POC output

signal mis-

match

Valve POC (proof of closure)

output terminal to burner

management control

energized while internal POC

relay is not energized.

Or POC output terminal to

burner management control

not energized while POC

relay is energized.

Possible internal fault,

malfunction of relay or

external mis-wiring of valve.

Remove power and shut-off gas supply as

necessary.

1.) Remove valve front electrical enclosure.

2.) Inspect external wiring between

valve POC terminal and burner

management system for proper seating,

pin engagement and cleanliness. Ensure

the valve POC terminal is not externally

powered. Correct any errors.

3.) Replace cover and restore power and

gas. Reset valve and burner management

system, monitoring for proper POC

operation in conjunction with valve LEDs

and burner management system inputs.

4.) If fault persists, replace valve main

electronics.

74