Installation

3–34

Power-up Checklist

Checking Flow Control I/P Transducers

NOTE:

Only follow this procedure if a Flow Control

system is installed.

1.

Turn on the main power on the PrecisionMix II 3K

controller.

2.

Turn off the air supply to the I/P transducers.

W ARNING

The next test will use free-flowing air from the I/P

transducer. Make sure the area is safe for this test.

3.

Remove the air line from the I/P transducer out-

lets. Turn on the air supply to the I/P transducer.

4.

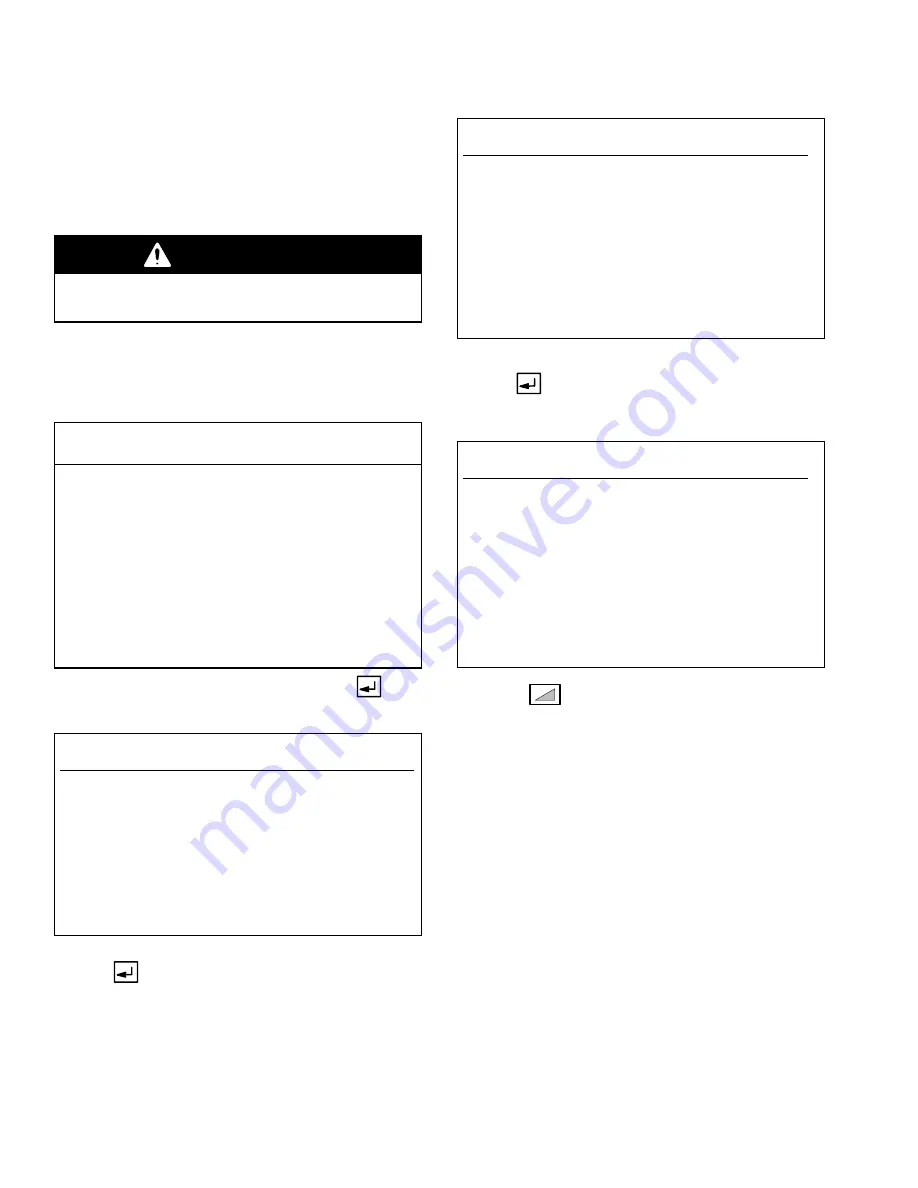

Go to the System Configuration Menu screen.

System Configuration Menu

SYSTEM CONFIGURATION

Station: 00

MENU

1.LANGUAGE

2.STATION NUMBER

3.DISPLAY UNITS

4.RECIPES

5.POTLIFE TIMER

6.FLOW RATE LIMITS

7.SOLVENT METER

8.PURGE SEQUENCE

9.MIXED LOAD VOL.

10.GUNS SETUP

11.MIX/PURGE

12.FLOW CONTROL

13.INTEGRATOR VOLUME

14.COLOR CHANGE

15.PASSWORD CHANGE

16.TIME AND DATE

17.DISPLAY SETUP

18.PRINT SETUP

19.AIR FLOW SWITCH

Select a menu item and press enter: > 12

5.

Type number 12, for

FLOW CONTROL

, then

.

C12:

Flow Control

SYSTEM CONFIGURATION

Station: 1

FLOW CONTROL OPTIONS

Select Flow Control Options:

1. OFF

2. Hand Gun Operation

3. Automatic Gun Operation

> 2

Press Enter to Accept Data and Edit

the Flow Control Options.

6.

Type the number for the desired flow control option

then

.

Flow Control Menu (FCMenu)

SYSTEM CONFIGURATION

Station: 1

FLOW CONTROL: MENU

Select Flow Control Options to Edit:

1. Source of Flow Control Data

2. Analog Input Scaling Range

3. Force Analog Output

4. Delay Time to Start Flow Control

5. Flow Meter Location

> 3

7.

Type number 3 for

Force Analog Output

then

.

FC1:

Flow Control Force Output

SYSTEM CONFIGURATION

Station: 1

FLOW CONTROL:FORCE OUTPUT

Select On to Begin Forcing the Outputs:

> ON

Enter a New Output Percentage to Force

the Flow Regulator:

Gun 1 = 100 %

8.

Select

ON

and enter

100%

to force the fluid

regulator open. Maximum air pressure should flow

from the I/P transducer. Enter

0%

to close the Fluid

regulator. There should be no air flow from the I/P

transducer.

9.

Re-install the I/P transducer air lines.

Содержание PrecisionMix ii

Страница 6: ...6 ...

Страница 7: ...1 1 Warnings Warnings 1 ...

Страница 8: ...1 2 Warnings ...

Страница 11: ...Overview 2 1 Overview 2 ...

Страница 12: ...2 2 Overview ...

Страница 15: ...Overview 2 5 ...

Страница 31: ...Installation 3 1 Installation 3 ...

Страница 32: ...Installation 3 2 ...

Страница 58: ...Installation 3 28 Notes ...

Страница 63: ...Installation 3 33 Power up Checklist Fig 3 23 CP Interface Step 5 Step 6 Step 4 Step 7 Step 10 ...

Страница 67: ...Operation 4 1 Operation 4 ...

Страница 68: ...Operation 4 2 ...

Страница 83: ...Operation 4 17 Notes ...

Страница 90: ...Operation 4 24 ...

Страница 91: ...Screen Map 5 1 Screen Map 5 ...

Страница 92: ...5 2 Screen Map ...

Страница 94: ...5 4 Screen Map ...

Страница 95: ...Run Monitor 6 1 Run Monitor 6 ...

Страница 96: ...Run Monitor 6 2 ...

Страница 103: ...Totalizers 7 1 Totalizers 7 ...

Страница 104: ...Totalizers 7 2 ...

Страница 108: ...Totalizers 7 6 ...

Страница 109: ...System Configuration 8 1 System Configuration 8 ...

Страница 110: ...System Configuration 8 2 ...

Страница 138: ...System Configuration 8 30 PrecisionMix II 3K Robotic Interface Integrated Color Change TI0494 Fig 8 1 ...

Страница 142: ...System Configuration 8 34 ...

Страница 143: ...Recipe Setup 9 1 Recipe Setup 9 ...

Страница 144: ...Recipe Setup 9 2 ...

Страница 165: ...10 1 Troubleshooting Troubleshooting 10 ...

Страница 166: ...10 2 Troubleshooting ...

Страница 182: ...10 18 Troubleshooting ...

Страница 183: ...11 1 Service Service 11 ...

Страница 184: ...11 2 Service ...

Страница 192: ...11 10 Service ...

Страница 193: ...12 1 Parts Parts 12 ...

Страница 194: ...12 2 Parts ...

Страница 207: ...12 15 Parts Notes ...

Страница 228: ...12 36 Parts ...

Страница 229: ...13 1 Utilities Software Utilities Software 13 ...

Страница 230: ...13 2 Utilities Software ...

Страница 254: ...13 26 Utilities Software ...

Страница 255: ...14 1 Technical Data Technical Data 14 ...

Страница 256: ...14 2 Technical Data ...

Страница 259: ...14 5 Technical Data Notes ...