FRIGOMAT

GX2, GX4

6

EN

1

PREPARATION FOR USE

Wash and sanitize the machine as indicated in IV

-

1 of this manual.

2

PRELIMINARY CHECKS

The following checks must be made every time you want to start

production.

2.1 Machine checks

Make sure that the gate valve of cold water for condensation is open.

Make sure the master switch is closed and that the machine is powered

correctly.

Make sure that the water drain plugs are assembled correctly and closed.

Make sure that the beaters are complete with the scrapers and are installed

correctly. Check that the knobs are tightened.

Verify that the covers are correctly installed.

2.2 Mix checks

To avoid any malfunction or damage to the machine, it is necessary to also

conduct the checks below on the product you wish to use:

-

Check that the mixture has been made and balanced.

-

Check the mixture is fluid, even and well combined.

-

Always mix before pouring the mixture in the tub.

To avoid bacterial contamination and to obtain maximum perfor-

mance from the machine, always keep the mixture stored at a

temperature below 5 °C (41 °F).

3

ICE CREAM PRODUCTION

3.1 Start

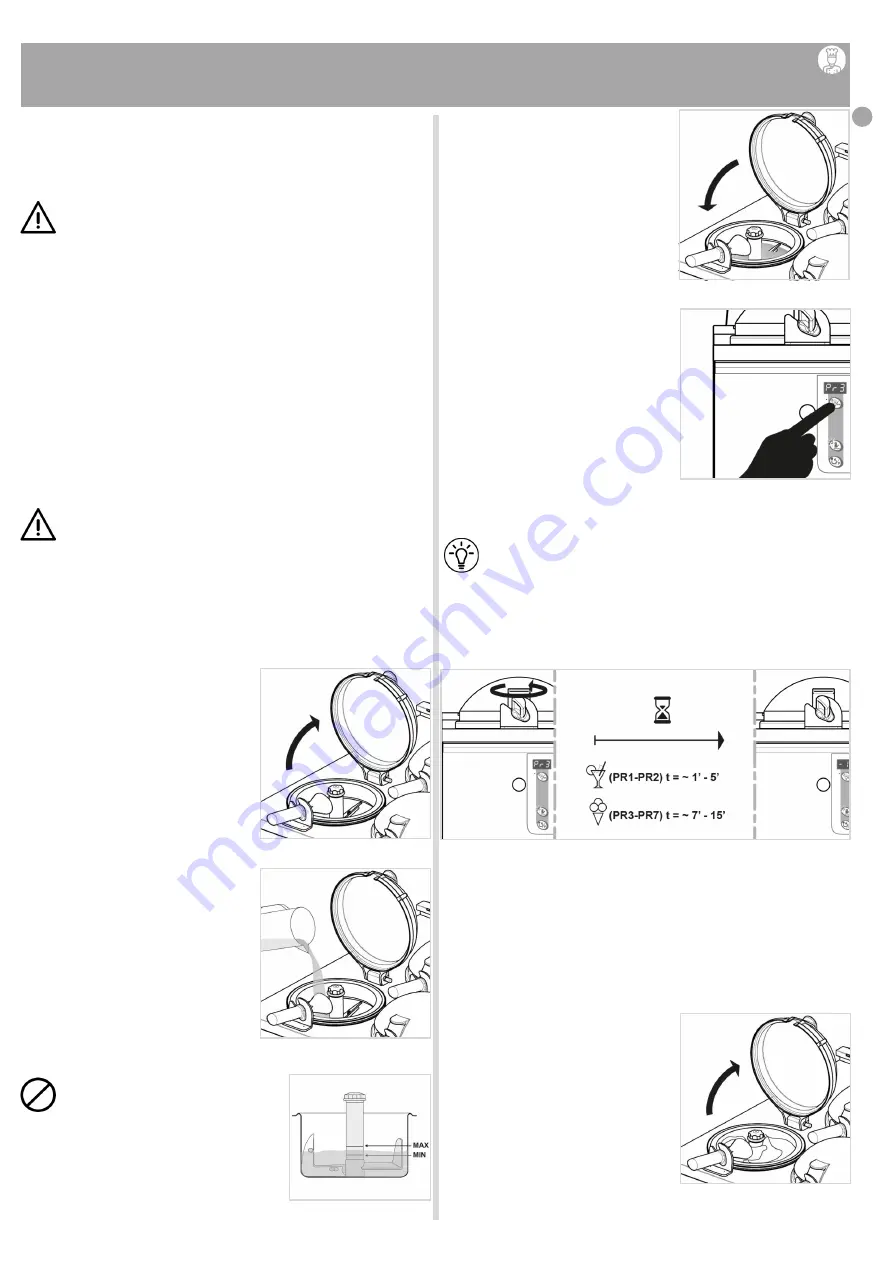

Lift the cover up to complete rotation, hol-

ding it by the handle positioned towards the

operator (fig.III/01).

pour the mixture into the batch freezing ves-

sels, strictly observing the minimum and

maximum amounts admitted per cycle and

stated in the following table:

Min: 1.5 kg

Max: 2.5 kg

Pay attention to not pour the mixture onto

the beater tree (fig.III/02).

To facilitate the operation, the beaters

are equipped with a minimum level and

maximum marks; any infringement of

these levels of charge, may cause mal-

function of the machine and in some cases

theirs serious damages. Minimum loads of

mixture may entail the premature wear of the

scrapers (fig.III/03).

Lower the cover, holding it by the handle

facing the operator (fig.III/04).

Press the PRODUCTION/OK key to start

the freezing of the product (fig.III/05).

The display shows a number between 1 and

7 referring to the set work program. Pro-

grams 1 and 2 are specific for the produc-

tion of granita, programs 3 to 7 are suitable

for sorbets and ice cream.

For the variation of the set program, refer to chap. III/3.3 of this manual.

The result of the freezing and the subsequent maintenance

phase depend largely on the selection of the working program.

After the necesary time to freeze, accorrding to the selected program, the

machine automatically switches to preservation mode (fig.III/06).

The gelato preservation function can maintain for a long time the product at

the correct temperature and consistency directly in the freezing cylinder.

3.2

Administration

To administer the product, lift the cover by

grasping it by the handle on the front of the

operator and accompany it until the maxi-

mum opening is allowed (fig.III/07).

Note: In order to avoid any risk for the ope-

rator, by lifting the cover stops the operation

of the beater: always remember to lower the

cover to allow the machine to resume the

interrupted perservation function.

III

USE

fig.III/01

fig.III/02

fig.III/03

fig.III/04

fig.III/05

fig.III/06

fig.III/07

for the operator

Содержание GX2

Страница 10: ...FRIGOMAT GX2 GX4 9 IT ...

Страница 28: ...EN FRIGOMAT GX2 GX4 9 ...

Страница 46: ...FRIGOMAT GX2 GX4 9 FR ...

Страница 56: ...FRIGOMAT GX2 GX4 19 EN IT FR DE ES CZ PL ...

Страница 74: ...FRIGOMAT GX2 GX4 xviii EN IT FR DE ES CZ PL ...

Страница 75: ...FRIGOMAT GX2 GX4 xix EN IT FR DE ES CZ PL ...

Страница 76: ...FRIGOMAT GX2 GX4 xx EN IT FR DE ES CZ PL ...