FRIGOMAT

GX2, GX4

4

EN

II

TRANSPORT AND INSTALLATION

The manufacturer will not be held liable for personal harm and/or

damage to objects deriving from incorrect installation and/or by

failure to comply with work accident

-

prevention standards.

This lack of compliance causes the warranty to terminate.

These operations are reserved exclusively for authorised from

the manifacturer and qualified personnel.

1

PRELIMINARY INSPECTION

The machine is transported at the risk and peril of the customer. If you noti-

ce any damage to the packaging, immediately inform the carrier.

Inform the carrier immediately after opening the package if the machine is

damaged even if a few days after delivery.

It is always preferable to accept goods SUBJECT TO CLEARANCE.

2

STORAGE

Once the appliance has been unpacked, the packaging must be kept in a

dry place out of the reach of children. If stored properly, it can be reused if

the machine is moved.

For unpacking and repacking procedures, refer to the document

"UNPACKAGING INSTRUCTIONS" applied to the packaging of the machi-

ne.

Storage temperature must be between 0 °C and +50 °C (32 °F

-

122°F), and

humidity must be between 30 and 95% with no dew.

3

INSTALLATION PLACE, POSITIONING

The handling of this machine must be carried out with extreme care and in

compliance with the regulations on the prevention of accidents at work in

force in the country in which it is installed. If necessary, equip yourself with

personal protective equipment (safety shoes, gloves, etc.). Two or more

persons are required to safely move this machine. Failure to comply may

result in personal injury or machine damage.

Make sure the appliance is positioned on a solid, stable, flat and levelled

surface.

Check that the place where the machine is installed is ventilated and cor-

rectly illuminated.

It is mandatory to position the machine far away from equipment which

emits electromagnetic radiation which could cause its malfunctioning.

Install the machine in areas where use and maintenance is possible only by

trained personnel. Failure to comply with this requirement may lead to physi-

cal damage or machine failure.

For Indoor Use Only: This machine is designed to operate indoors under

normal ambient temperatures of 16 °C e 32 °C (61 °F

-

90 °F).

The freezer has successfully performed in high ambient temperatures of

104 °F (40 °C) at reduced capacities.

Humidity must be between 30 and 85% with no dew.

Install the machine in places that are not excessively ventilated, protect it

against drafts and avoid direct sunlight.

4

INSTALLATION

This machine should be installed in accordance with the existing local co-

des. Please contact your local authorities.

Block the machine by acting on the relevant brake lever on the rear wheels.

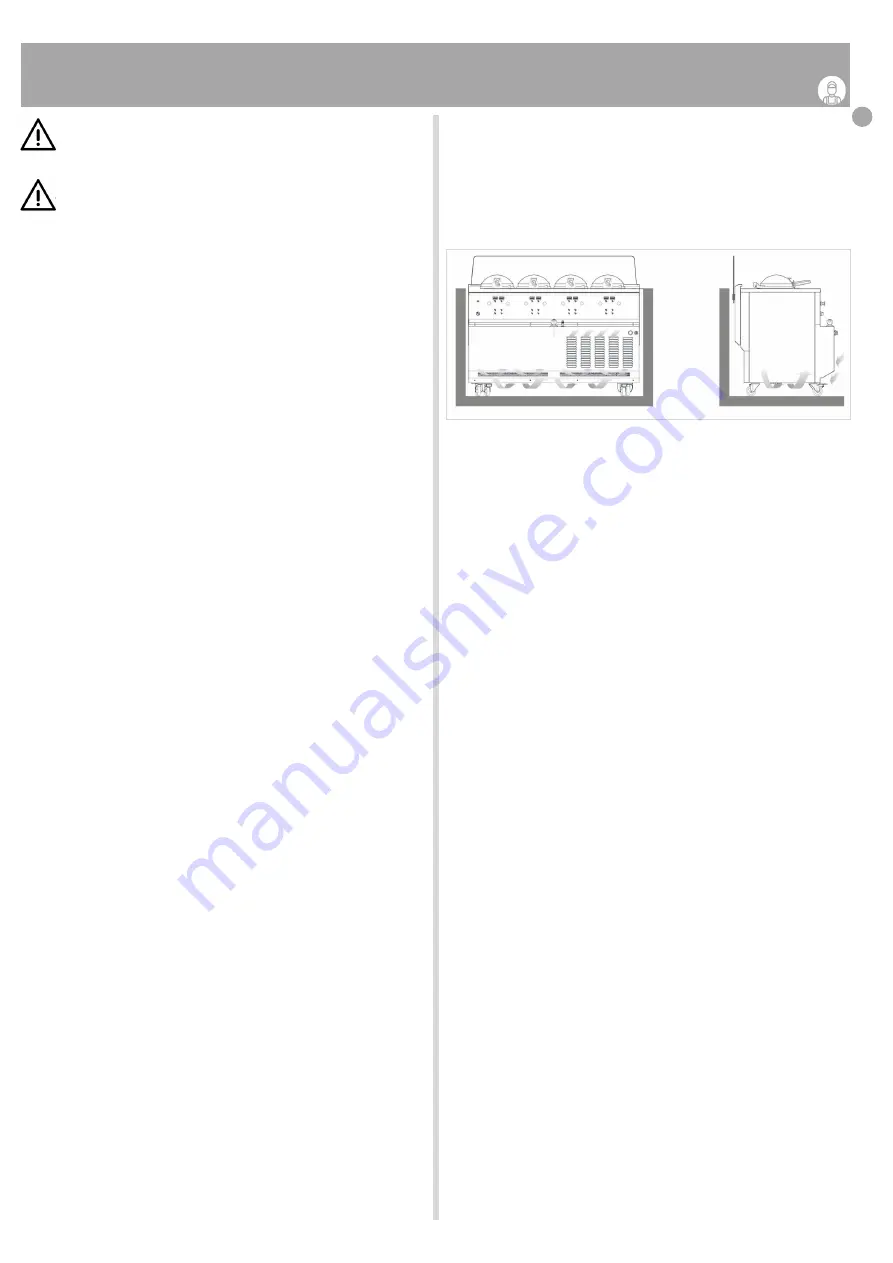

In case of recessed installation, ensure adequate circulation of fresh air to

the space below the machine and to the front panel on the operator's side

(fig.II/01)

4.1

Water Connections

The machine must be connected to the water mains in compliance with the

regulations in force in the country where the machine is installed.

Connect the machine to the drinking water mains with a dedicated line, fitted

upstream of a shut

-

off cock placed in a position easily reachable by the

operator.

Check that the mains supply of the cold water line has pressure values

between 1 and 3 BAR (between 0.1 and 0.3 MPa) and temperature between

13 °C and 20 °C (55 °F

-

68 °F).

Connect the machine to the water supply using only the new pipes supplied,

in compliance with the IEC 61770 standard; never use obsolete or worn out

pipes again. Use suitable DIN 3017 screw clamps.

Connect the cold water supply hose to the hose with 1/2 "connection.

Depending on local water conditions, it may be advisable to install a water

strainer to prevent foreign substances from clogging the automatic water

valve. There will be only one water

-

in and one water

-

out connection.

Provide a non

-

return water device on the water supply line, in compliance

with the regulations in force in the country where the machine is installed.

Connect the corrugated condensation water drain hose to the waste water

supply. The water drain pipe must have a minimum slope of 3 cm for each

meter in length.

Do Not install a hand shutoff valve on the water

-

out line.

After having connected the water inlet and outlet pipes, with the machine

stopped, open the cut

-

off cock and make sure that water does not leak from

the drain.

Never shut the water cut

-

off cock while the machine is running

4.2

Electrical connections

Each machine must be connected to a power line dedicated to sanitary

power, a standard and in perfect working order.

Check the exact correspondence between the voltage and power of the

mains compared to the values carried on the data plate applied on the side

of the panel.

Connect the machine to the electrical power supply system. Install a omni-

polar master switch upstream the appliance with minimum contact opening

of 3 mm of adequate power, with a fuse and circuit breaker protective sy-

stem. Use an approved interlocking plug to allow only the

The cable must be well laid, without being rolled

-

up or overlapped. It must

not be exposed to blows or tampering. It must not be in the vicinity of liquids

or water and heat sources. It must not be damaged in any way. If so, before

connecting the machine to the mains, have it replaced by qualified person-

nel with another having suitable section and type H07RN

-

F.

fig.II/01

for the technician

Содержание GX2

Страница 10: ...FRIGOMAT GX2 GX4 9 IT ...

Страница 28: ...EN FRIGOMAT GX2 GX4 9 ...

Страница 46: ...FRIGOMAT GX2 GX4 9 FR ...

Страница 56: ...FRIGOMAT GX2 GX4 19 EN IT FR DE ES CZ PL ...

Страница 74: ...FRIGOMAT GX2 GX4 xviii EN IT FR DE ES CZ PL ...

Страница 75: ...FRIGOMAT GX2 GX4 xix EN IT FR DE ES CZ PL ...

Страница 76: ...FRIGOMAT GX2 GX4 xx EN IT FR DE ES CZ PL ...