Operating manual

CNC 8070

5.

M

ANUAL

(J

OG

) MODE.

TOOL

CALI

B

RAT

IO

N

(S

OFT

V03.0

X

)

80

Probe selection

Two probes may be configured at the CNC. The probe active at the time is used for

calibration. The active probe may be changed via part-program or MDI using the

instruction

#SELECT PROBE

.

Geometrical configuration of the axes: "plane" or "trihedron".

At the lathe model, the geometrical configuration of the axes may be either of the

"plane" or "trihedron" type depending on the availability of a third main axis, usually

the ·Y· axis. The different calibration modes adapt to the current configuration

showing the necessary data for each one of them.

Configuration of "plane" type axes. The longitudinal axis.

In this configuration, the second axis of the channel is considered as longitudinal axis.

If the X (first) and Z (second) axes have been defined, the work plane will be the ZX

and Z will be the longitudinal axis. Tool length compensation is applied on this

longitudinal axis when using milling tools. With lathe tools, tool length compensation

is applied on all the axes where a tool offset has been defined.

When using milling tools on a lathe, the longitudinal compensation axis may be

changed by means of the #TOOL AX instruction or the G20 function.

#SELECT PROBE [1]

Selects the first probe.

#SELECT PROBE [2]

Selects the second probe.

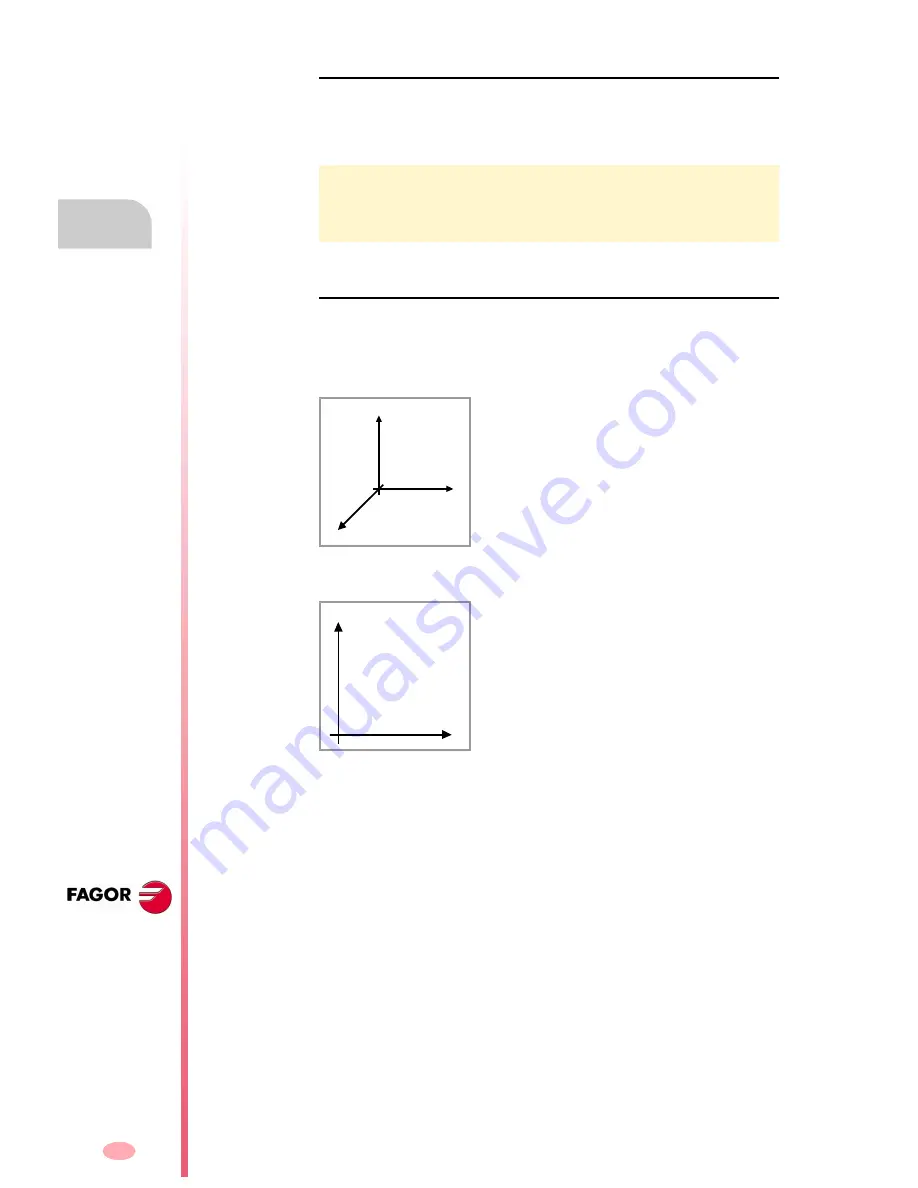

Geometrical configuration of "trihedron" type

axes.

It is the typical configuration of a milling machine or of

a lathe that has a third main axis (·Y· axis).

There are three axes forming a Cartesian XYZ type

trihedron like on a milling machine. There may be more

axes besides those forming the trihedron.

With this configuration, the planes behave in the same

way as on a milling machine except that the usual work

plane will be G18 (if it has been configured like that).

Geometrical configuration of "plane" type axes.

It is the typical configuration of a lathe.

There are two axes forming the usual work plane. There

may be more axes, but they cannot be part of the

trihedron; there must be auxiliary, rotary, etc.

With this configuration, the active plane will be formed

by the first two axes defined in the channel. If the X (first)

and Z (second) axes have been defined, the work plane

will be the ZX (Z as abscissa and X as ordinate).

The work plane is always G18; the plane cannot be

changed via part-program.

Z

X

Y

Z

X

Содержание CNC 8070

Страница 1: ...CNC 8070 REF 0509 SOFT V03 0X OPERATING MANUAL Soft V03 0x Ref 0509...

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 12: ......

Страница 14: ......

Страница 16: ......

Страница 22: ......

Страница 26: ......

Страница 28: ......

Страница 30: ......

Страница 32: ......

Страница 34: ......

Страница 66: ...Operating manual CNC 8070 2 HOW TO OPERATE THE CNC Keyboard shortcuts SOFT V03 0X 32...

Страница 96: ...Operating manual CNC 8070 3 AUTOMATIC MODE Program selection and execution SOFT V03 0X 62...

Страница 112: ...Operating manual CNC 8070 4 MANUAL JOG MODE Automatic loading of zero offsets or fixture offset tables SOFT V03 0X 78...

Страница 194: ...Operating manual CNC 8070 7 MDI MODE Full MDI screen SOFT V03 0X 160...

Страница 236: ...Operating manual CNC 8070 9 TOOL AND MAGAZINE TABLE Operations with the magazine table SOFT V03 0X 202...

Страница 250: ...Operating manual CNC 8070 10 UTILITIES MODE Utilities Softkeys SOFT V03 0X 216...

Страница 288: ...Operation manual 8070 CNC 11 PLC Messages service SOFT V03 0X 254...

Страница 300: ...Operating manual CNC 8070 12 MACHINE PARAMETERS Operations with tables SOFT V03 0X 266...

Страница 346: ...Operating manual CNC 8070 14 DDSSETUP Command generator SOFT V03 0X 312...

Страница 357: ...CNC 8070 SOFT V03 0X 323 Operating manual...

Страница 358: ...CNC 8070 SOFT V03 0X 324 Operating manual...