,QVWDOODWLRQ

#

3URFHGXUH

##

6046

953#

9HFWRU

#

'ULYH

#0#

+$

7968;7

7\SH

#;/<#

DQG

#43#

%UDNH

#

8QLW

#

5DWLQJ

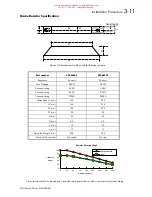

The type 8, 9 and 10 brake units have the following specification -

Maximum braking power: 150%

Operating voltage:

750 - 820 V dc

Maximum duty cycle:

30%

Maximum on time:

20 Seconds

'ULYH

#

VL]H

0D[

1#

%UDNH

#

&XUUHQW

#

:83

9GF

0LQLPXP

#

%UDNH

5HVLVWDQFH

6L]H

#;#2#3<33

553

$

6173#

RKPV

6L]H

#;#2#4433

597

$

51;7#

RKPV

6L]H

#;#2#4653

633

$

5183#

RKPV

6L]H

#<#2#4933

693

$

5133#

RKPV

6L]H

#<#2#4;33

773

$

41:3#

RKPV

6L]H

#<#2#5333

783

$

4193#

RKPV

6L]H

#43#2#5833

858

$

4176#

RKPV

6L]H

#43#2#5;33

9:8

$

4144#

RKPV

%UDNH

#

5HVLVWRU

#

6HOHFWLRQ

#0#

)XUWKHU

#

QRWHV

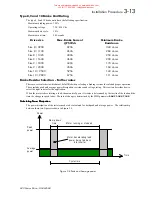

There are several criteria which must be fulfilled when selecting a braking resistor for safe and proper operation.

These include peak and average power dissipation, resistance and voltage rating. This section describes how to

select the right resistor for the application.

When the motor is decelerating a load, the amount of power it creates is determined by the inertia of the load and the

time the change in speed takes. The rate of change is determined by the MMI parameter

RAMP DOWN TIME

.

&DOFXODWLQJ

#

3RZHU

#

'LVVLSDWLRQ

&DOFXODWLQJ

#

3RZHU

#

'LVVLSDWLRQ

&DOFXODWLQJ

#

3RZHU

#

'LVVLSDWLRQ

&DOFXODWLQJ

#

3RZHU

#

'LVVLSDWLRQ

The power dissipation of the resistor needs to be calculated for both peak and average power. The relationship

between these two figures is shown in Figure 3.4.

P o w e r

T i m e

R a m p d o w n

time

Motor running or stopped

Cycle time

P e a k

power

Average

power

Motor decelerating load:

power being fed back

into inverter

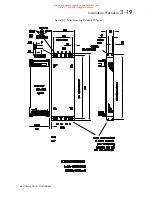

)LJXUH

#617#

3HDN

#

DQG

#

$YHUDJH

#

SRZHU

This manual was downloaded on www.sdsdrives.com

+44 (0)117 938 1800 - [email protected]