6049##

,QVWDOODWLRQ

#

3URFHGXUH

953#

9HFWRU

#

'ULYH

#0#

+$

7968;7

(0&

#

,167$//$7,21

#

*8,'(/,1(6

,QWURGXFWLRQ

This section provides installation guidelines for drive modules and systems to maximise their 'Electro Magnetic

Compatibility' (EMC) in their intended operating environment. All installers must read this section and apply the

advice which is relevant to their application. Pass on this information to others as is appropriate.

All power drive systems have the potential to produce electrical emissions, both radiated and conducted back into

the AC supply. This is due to the inherent operation of all drives by switching large voltages and currents rapidly

in order to control the motor. Because the drives internal control electronics operates continuously in very close

proximity to the electrically noisy power switching elements, drives are inherently immune to any additional

external electrical noise.

Great care has been taken in the design and selection of suitable EMC filters to provide the correct level of

interface suppression, ease of installation and to ensure that electrical safety is not compromised. The EMC

performance can only be guaranteed to be within the limits specified when the 620 drive modules are installed

together with the recommended EMC filters in accordance with the following instructions.

The subject of EMC is explored in more detail in a separate Eurotherm Application Manual entitled "EMC

Installation Guidelines for modules and systems’, part number HA388879, available from your local Eurotherm

office.

(0&

#

)LOWHUV

#

WR

#

5HGXFH

#

/LQH

#

&RQGXFWHG

#

1RLVH

An EMC supply filter may be used with each 620 drive module to reduce the line conducted noise. The

recommended filters are listed in table 3.3 below.

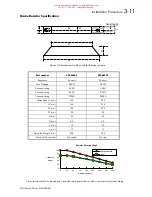

7DEOH

#616#

$&

#

6XSSO\

#

)LOWHU

#

3DUW

#

1XPEHUV

#

IRU

#

&RQIRUPDQFH

#

ZLWK

#

(1

88344#

&ODVV

#

%

#+

VXLWDEOH

#

IRU

#

ERWK

JHQHULF

#

HQYLURQPHQWV

,

(XURWKHUP

3URGXFW

5DWLQJ

:DWW

/RVV

(XURWKHUP

#

)LOWHU

3DUW

#

1XPEHU

953#

7\SH

#7

31:8

N:

#0#818

N:

#+6;3

9

#

WR

#793

9

,#)

31:8

N:

#0#515

N:

#+53;

9

#

WR

#573

9

,#

FRQVWDQW

#

WRUTXH

53

:

&2

6;;<99

8

354

953#

7\SH

#7

:18

N:

#+6;3

9

#

WR

#793

9

,#)#7

N:

#+53;

9

#

WR

#573

9

,

FRQVWDQW

#

WRUTXH

68

:

&2

6;;<99

8

368

953#

7\SH

#8

$OO

58

:

&2

6;;<99

8

378

953#

7\SH

#9

$OO

:8

:

&2

797386

8

3<8

953#

7\SH

#:

$OO

48;

:

&2

797386

8

533

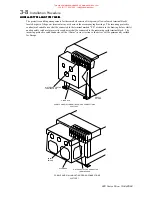

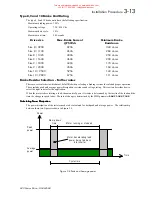

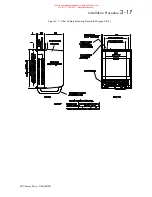

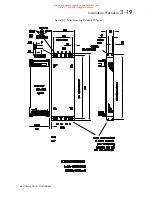

The recommended EMC filters for the type 4 and 5 620 are to be mounted behind the drive module (underfloor

mounting) and share the same footprint. They are suitable as standard for cubicle mount applications, as shown in

figure 3-7. For wall mounting a purpose designed pressed steel conduit (Part No. BA388844) is supplied with

the gland box, for mounting between the filter body and gland box is shown in the mechanical mounting drawing

figures 3-8.

This manual was downloaded on www.sdsdrives.com

+44 (0)117 938 1800 - [email protected]