Thickness Mode:

If you select this mode, you must enter the thickness of your object in the Processes

Section under each individual process. If all processes in your job need to be focused at the same level,

it may save you time to enter the thickness before splitting the job into multiple processes. For more

information on splitting processes see

“Dividing Your Job Into Processes” on page 66.

For more

information about Thickness Mode,

Please note:

The material thickness is still required when using the Vector Cutting Table. If a

thickness is not specified the system will Auto Focus to the top of the grid, not to the top of your

material. To enter the material thickness of the object you will be engraving/marking/cutting

use a pair of calipers for an accurate measurement and enter this value in the “Thickness”

box in the driver.

Plunger:

When you enter Jog mode and have jogged the lens carriage above your material, press the

Auto Focus button to use the plunger Auto Focus. The table will then rise until the material touches the

plunger (pictured below), then set the table to the correct height. Your job should now be in focus. You

may also set up Plunger Mode in the Dashboard. For more information,

WARNING:

Do not use the Auto Focus plunger to focus on the Vector Cutting Table or Slat

Table.

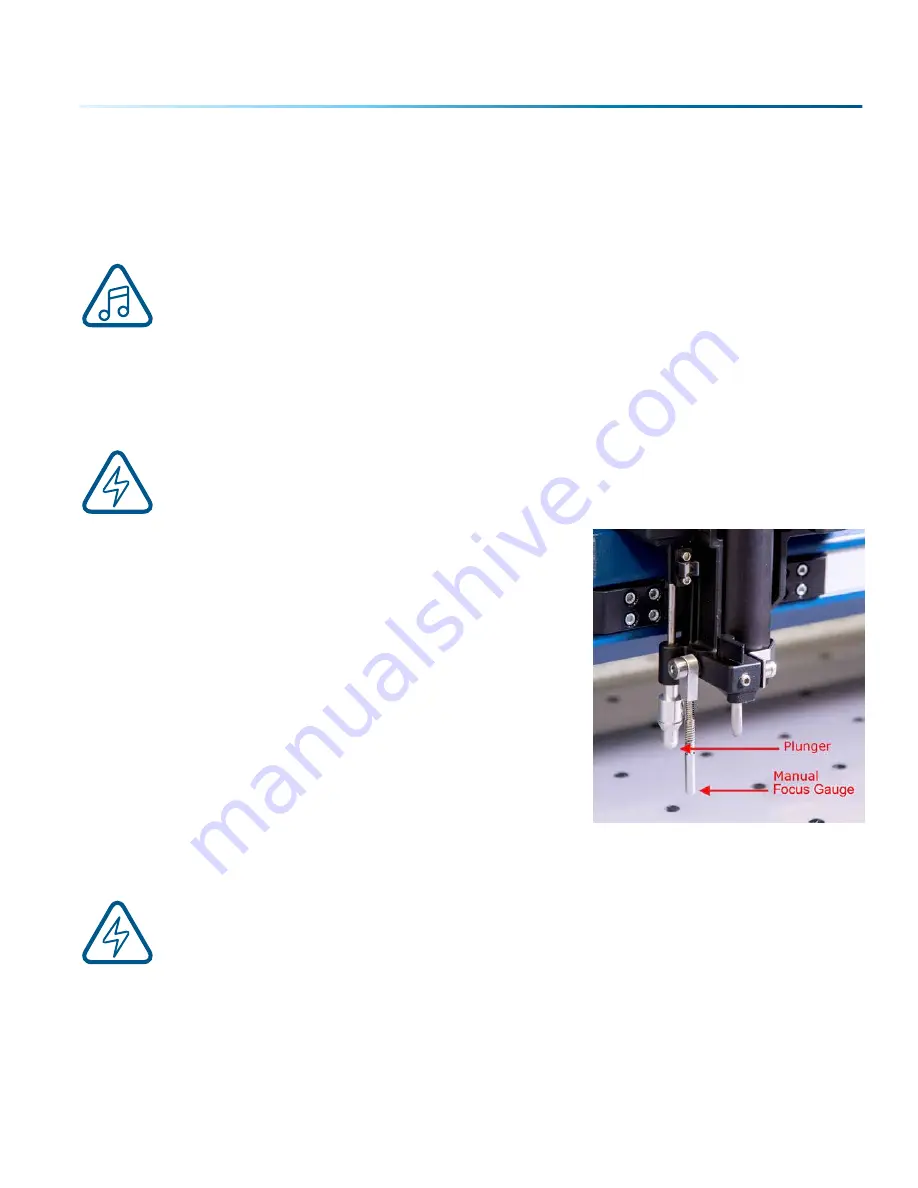

Manual Focus

This photo shows the Manual Focus Gauge that is used to

determine the correct distance from the focus lens to the top of

your material. This gauge is included with your system.

Place the object to be cut or engraved anywhere on the table of

the machine. Select the

Jog

button on the touch screen and use

the

Joystick

to bring the focus gauge to the object. Deselect the

Jog button, then select the

Focus

button on the touch screen and

move the

Joystick

up or down to move the table appropriately

until your material just touches the bottom of the gauge.

The speed at which the table rises or lowers can be controlled

by applying varying pressure upwards or downwards on the

Joystick

.

You may also fine-tune the table height in the Focus Menu. Once the focus position has been established,

flip the gauge back up into its locked position. Press the Focus button to leave the menu and then press

the

Reset

key to bring the laser head back to its Home Position.

WARNING:

Do not leave the Manual Focus Gauge down when running jobs or when using

Auto Focus!

If your material has a taper or curve, pick an intermediate point between the highest and lowest points

being engraved and focus on that point. In general, the area of the material being engraved needs to be

relatively flat. If the area being engraved differs in height by more than about an .125” (3 mm), the image

will begin to look “fuzzy” or out of focus.

- 111 -

SECTION 8: SYSTEM FEATURES

Содержание Fusion Pro 32

Страница 2: ......

Страница 6: ......

Страница 13: ...The following diagrams show the location of each specific label Fusion Pro 32 7 SECTION 1 SAFETY ...

Страница 14: ...Fusion Pro 48 8 SECTION 1 SAFETY ...

Страница 15: ... 9 SECTION 1 SAFETY ...

Страница 18: ......

Страница 28: ......

Страница 60: ......

Страница 98: ......

Страница 108: ......

Страница 132: ......

Страница 162: ......

Страница 184: ......

Страница 202: ......

Страница 214: ......

Страница 216: ......

Страница 242: ......