RIVER IDROTECH 18 - 24 - 24H2O

20

7.7

WATER CHARACTERISTICS

The characteristics of the water used to fill the system are very important to prevent the build-up of mineral salts and the forma-

tion of incrustations along the pipes, in the boiler and in the heat exchangers.

Therefore, please ASK YOUR PLUMBER FOR HIS ADVICE CONCERNING:

Hardness of water circulating in the system, to prevent problems of incrustation and limescale, especially in

the domestic water heat exchanger. (> 25° French).

Installation of a water softener (if water hardness exceeds 25° French).

Filling the system with treated water (demineralised).

Possibly providing an anti-condensation circuit.

Installation of hydraulic shock absorbers to prevent water hammering along the fittings and pipes.

If you have very extensive systems (with a large amount of water) or which require frequent refilling, the installation of water

softening systems.

It should be remembered that incrustations drastically reduce performance due to their extremely low thermal

conductivity.

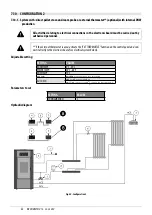

7.8

SYSTEM CONFIGURATION

Upon installation, the product must be set according to the type of system, selecting the appropriate parameter in the “SETTINGS”

menu.

The possible configurations are 5, as described below:

CONFIGU-

RATION

DESCRIPTION

1

Room temperature management via probe on the stove or by enabling an external room thermostat.

2

2.1 Room temperature management via probe on the stove or by enabling an external room thermostat: instantaneous

DHW production with INTEGRATED plate exchanger.

2.2 Room temperature management via probe on the stove or by enabling an external room thermostat; DHW production

for boiler or storage tank with EXTERNAL thermostat CONNECTED TO THE ELECTRONIC BOARD (optional).

DISCONNECT ANY 3-WAY VALVES AND INTERNAL FLOW SWITCHES

3

Room temperature management via probe on the stove or by enabling an external room thermostat; DHW production for

boiler OR STORAGE TANK with ntc probe CONNECTED TO THE ELECTRONIC BOARD (10 kΩ ß3435).

DISCONNECT ANY 3-WAY VALVES AND INTERNAL FLOW SWITCHES

4

External Puffer management controlled by thermostat CONNECTED TO THE ELECTRONIC BOARD.

5

External Puffer management controlled by ntc probe CONNECTED TO THE ELECTRONIC BOARD (10 kΩ ß3435).

1-2-3-4-5 Example of connection with AUXILIARY GAS wall-mounted boiler

Following the explanations of the previous chapter, here are the various system configurations to make it easier to recognise the

system the boiler is installed on and avoid an incorrect selection. We have indicated which parameters are automatically activated,

disabled or blocked for each configuration.

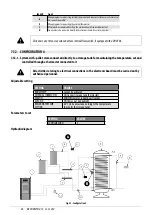

7.9

CONFIGURATION 1

7.9.1 System with: direct pellet stove and room probe or external thermostat** (optional)

All activities relating to electrical connections in the electronic board must be carried out by

authorised personnel.

** If the external thermostat is used, activate the “EXT THERMOSTAT” function on the control panel and con-

nect it directly to the electronic board (see electrical system below).

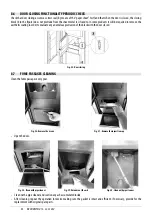

Содержание RIVER IDROTECH 18

Страница 42: ...RIVERIDROTECH18 24 24H2O 42 10 2 ELECTRONIC BOARD WITH DHW Fig 68 ElectricalboardwithDHW ...

Страница 46: ...NOTE ...

Страница 47: ...NOTE ...