RIVER IDROTECH 18 - 24 - 24H2O

19

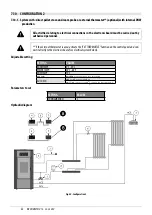

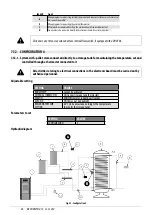

7.5

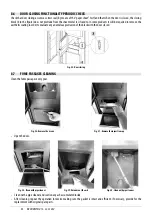

WASHING THE SYSTEM

The connections must be easy to disconnect via pipe unions with swivel fittings.

Install suitable gate valves on the heating system pipes. A safety valve must be installed on the system.

To protect the heating system from harmful corrosion, build-ups or deposits, it is extremely important before installing the ap-

pliance to wash the system in compliance with the UNI 8065 standard (water treatment in heating systems for domestic use),

using appropriate products.

The use of FERNOX PROTECTOR F1 (available at our authorised centres) product is recommended, this provides long-term protec-

tion of heating systems against corrosion and calcium build-up. It prevents the corrosion of the metal parts of the appliance, i.e.

the ferrous metals, copper and copper and aluminium alloys. It also reduces the noise produced by the boiler. Refer to the instruc-

tions on the product. Cleaning should be performed by a qualified technician.

We also recommend the use of FERNOX CLEANER F3 and LEAK SEALER F4, always available from our authorised distribution centres.

FERNOX F3 is a neutral product for rapid and efficient cleaning of heating appliances. It has been designed to eliminate residues,

oily deposits and incrustations from existing appliances of all ages. It can help restore the heating efficiency of the boiler and

reduce the noise it generates.

FERNOX F4 is intended to be used with all heating appliances to seal micro fractures that cause small and inaccessible leaks.

7.6

FILLING THE SYSTEM

To fill the system, the stove may be equipped with a terminal (optional) with a non-return valve (D) to manually fill the heating

system (if there is no terminal, use the filling valve on the main boiler). During this operation, the automatic bleed valve under the

top ensures that any air in the system is expelled.

To allow the valve to bleed, we recommend loosening the grey cap by a turn and leaving the red cap tight (see figure). The filling

pressure when the system is

COLD

must be

1 bar

. During operation, should system pressure drop (due to the gas dissolved in the

water evaporating) below the above indicated minimum value, the user must bring it back to the initial value, using the filling

valve.

For proper stove operation when it is

HOT

, pressure in the boiler must be

1.5 bar

.

To monitor system pressure, the terminal (optional) is equipped with a pressure gauge (M).

When filling is complete, always shut off the valve.

Fit the system with a 2 bar safety valve connected to an accessible outlet.

It is normal for there to be noises and gurgling until all the air in the system has been expelled.

Fig. 37 - Terminal with filling valve (D) and pressure gauge (M)

Fig. 38 - Manual bleed valve (located under the top) (Idro Prince

3

16-23-23

H2O, Aquos

3

16-23-23 H2O, Idron 16-22 Airtight, Hidrofire 22.8)

SETTING

VALUES

H

Water temperature probe

I

Flue gas temperature probe

G

Air venting valve

Содержание RIVER IDROTECH 18

Страница 42: ...RIVERIDROTECH18 24 24H2O 42 10 2 ELECTRONIC BOARD WITH DHW Fig 68 ElectricalboardwithDHW ...

Страница 46: ...NOTE ...

Страница 47: ...NOTE ...