Page 38

SECTION IV: INSTALLATION

GAS CONNECTIONS

CAUTION

Do not use this water heater with any gas other than the type listed on the rating label.

Check the rating label on the front of the water heater and make sure the gas to be

used matches the gas stated on the rating label. Consult your local gas company or

Bock Water Heaters with any questions.

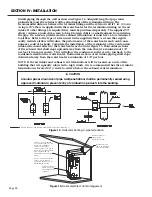

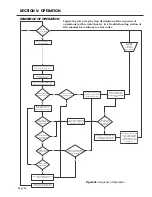

A manual valve, union, and a

sediment trap shall be provided

in front of the gas valve. All gas

piping must conform to local

codes and/or the National Fuel

Gas Code ANSI 223.1/NFPA 54

or CSA B149.1. Figure 31 shows

the installation of a sediment

trap to the gas piping on the

water heater.

The gas supply piping to the

heater must be sized such

that the pressure at the valve

is sufficient when all other

appliances are operating.

Undersized gas piping

will reduce water heater

performance and result

in nuisance lockouts.

Refer to Section III: Pre-Installation / Gas Supply Line for pipe size requirements.

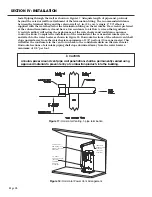

Verify that the gas service and meter are sized properly for the total load. If the gas supply

pressure is greater than 14” W.C., the water heater must have a supply gas regulator installed

in the gas supply line for each water heater. The regulator must be rated at or above the input

rating (Btu/hr) of the water heater that it serves. Inlet and outlet connections on the regulator

shall not be less than the minimum gas supply line size for the water heater. The Maxitrol

325-7 series of regulators with 1-1/2” or 2” connections is recommended.

For ease of measurement, install a tee with a pipe fitting and a manual shutoff valve between

the main manual shut-off valve to the water heater and the pressure regulator. The pipe

fitting should be adaptable to a pressure gauge for measuring incoming gas pressure. If further

measurement of gas pressure is required due to lack of adequate pressure, measurement at the

inlet of the gas control is recommended. Refer to Section III: Pre-Installation / Gas Supply Line

for minimum pressure requirements.

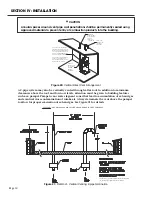

During pressure testing of the gas supply piping, close the manual gas shut-off valve to the

water heater to avoid over pressuring the gas valve. Test pressure shall

not exceed

1

⁄

2

PSIG

(14” W.C). Pressurizing the gas valve over 1/2 PSIG during pressure testing is not recommend.

To test at a pressure greater than

1

⁄

2

PSIG, close the manual shut-off valve and disconnect the

gas control. Turn on gas and inspect piping for leaks by “painting” each joint with a soapy

water solution and check for bubbles.

WARNING

DO NOT use an open flame to check for leaks. Serious injury or death could result from

fire or explosion.

The pipe thread compound that is used on gas piping must be of the type resistant to

propane gas. Do not use teflon tape on gas piping.

L

DETAIL L

SCALE 1 : 10

SEDIMENT TRAP

PIPE CAP

TEE

UNION

MAIN GAS SHUTOFF VALVE

REGULATED GAS SUPPLY LINE

Figure 31: Gas Piping with Sediment Trap

Содержание OT600-A

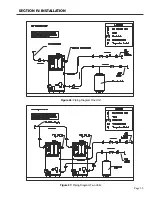

Страница 35: ...SECTION IV INSTALLATION Page 35 Figure 26 Piping Diagram One Unit Figure 27 Piping Diagram Two Units ...

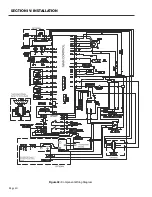

Страница 40: ...Page 40 SECTION IV INSTALLATION Figure 32 Component Wiring Diagram ...

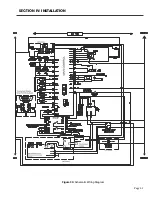

Страница 41: ...Page 41 Figure 33 Schematic Wiring Diagram SECTION IV INSTALLATION ...

Страница 62: ...Page 62 ...