Manual 2100-419E

Page

35 of 48

OPEN LOOP

(Well System Applications)

WATER CONNECTIONS

It is very important that an adequate supply of clean,

noncorrosive water at the proper pressure be provided

before the installation is made. Insufficient water, in

the heating mode for example, will cause the low

pressure switch to trip, shutting down the heat pump. In

assessing the capacity of the water system, it is

advisable that the complete water system be evaluated

to prevent possible lack of water or water pressure at

various household fixtures whenever the heat pump

turns on. All plumbing to and from the unit is to be

installed in accordance with local plumbing codes. The

use of plastic pipe, where permissible, is recommended

to prevent electrolytic corrosion of the water pipe.

Because of the relatively cold temperatures encountered

with well water, it is strongly recommended that the

water lines connecting the unit be insulated to prevent

water droplets form condensing on the pipe surface.

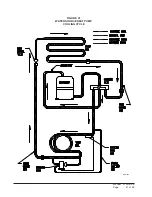

Refer to piping, Figure 24. Slow closing

Solenoid

Valve

(6)

with a 24 V coil provides on/off control of

the water flow to the unit. Refer to the wiring diagram

for correct hookup of the valve solenoid coil.

Constant Flow Valve (7)

provides correct flow of

water to the unit regardless of variations in water

pressure. Observe the water flow direction indicated by

the arrow on the side of the valve body. Table 8 is a

table showing the flow rate of each valve. Two

constant flow rate valves may be installed in parallel to

increase the flow. For example, when a 8603-007 (6

GPM) and 8603-011 (5 GPM) are installed in parallel

the total flow will be 11 GPM.

FIGURE 24

PIPING DIAGRAM

MIS-1569

TO WATER COIL

FROM WATER COIL

COPPER WATER COIL LIMITATIONS

Copper water coils are available as a factory installed

option. The unit model number will indicate the coil

option as the next to last character; “X” is for standard

coil constructed of Cupronickel material and “4” is from

a water coil constructed of copper.

The Cupronickel coil is suitable for all applications.

The copper coil is suitable for applications using

ground loop and cooling tower only and is never to

be used in an open well application.

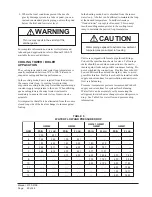

TABLE 8

CONSTANT FLOW VALVES

1

The pressure drop through the constant flow

valve will vary depending on the available

pressure ahead of the valve. Unless

minimum of 15 psig is available immediately

ahead of the valve, no water will flow.

.

o

N

t

r

a

P

e

l

b

a

l

i

a

v

A

.

n

i

M

G

I

S

P

e

r

u

s

s

e

r

P

e

t

a

R

w

o

l

F

M

P

G

7

0

0

-

3

0

6

8

5

1

1

6

8

0

0

-

3

0

6

8

5

1

1

8

0

1

0

-

3

0

6

8

5

1

1

4

1

1

0

-

3

0

6

8

5

1

1

5

9

1

0

-

3

0

6

8

5

1

1

3

Содержание QW242

Страница 6: ...Manual 2100 419E Page 6 of 48 FIGURE 1 UNIT DIMENSIONS ...

Страница 9: ...Manual 2100 419E Page 9 of 48 FIGURE 4 INSTALLATION OF UNIT THROUGH WALL WITH WALL SLEEVE MIS 1564 ...

Страница 21: ...Manual 2100 419E Page 21 of 48 FIGURE 15 REMOTE THERMOSTAT WIRING DIAGRAM X OPTION ...

Страница 22: ...Manual 2100 419E Page 22 of 48 FIGURE 16 REMOTE THERMOSTAT WIRING DIAGRAM A THERMOSTAT OPTION 4102 021A ...

Страница 23: ...Manual 2100 419E Page 23 of 48 4102 022C FIGURE 17 REMOTE THERMOSTAT WIRING DIAGRAM D THERMOSTAT OPTION ...

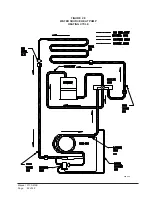

Страница 41: ...Manual 2100 419E Page 41 of 48 FIGURE 27 WATER SOURCE HEAT PUMP COOLING CYCLE MIS 329 ...

Страница 42: ...Manual 2100 419E Page 42 of 48 FIGURE 28 WATER SOURCE HEAT PUMP HEATING CYCLE MIS 328 ...